History of PCB

09/07/2019, hardwarebee

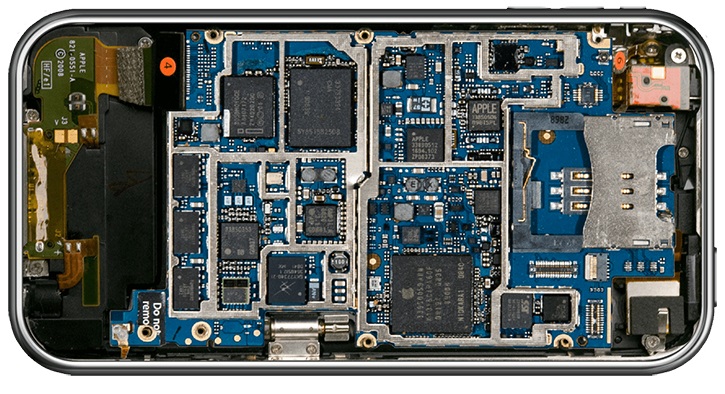

PCB stands for Printed Circuit Board. A Printed Circuit Board or PCB exist inside almost any and every electronic device or gadget that you may use in your routine and professional life. The PCB lies in a central position in most electronics and, thus, is an extremely critical component. It is the component that is allowing electricity to flow through the circuits, subsequently making the operations and functions of the device possible to be executed or performed.

Considering how important it is to any and every piece of electronics you own, here is a little guide on what PCBs are and how they actually came to be.

What are PCBs?

A Printed Circuit Board is essentially a substrate whose job is to support the various electronic components that constitute the electronic product and its circuits, allowing an electric current to flow through on its surface and power each of the individual components in a conductive manner. The circuits are etched onto the surface of the substrate using conductive tracks and pads which are used to connect the various components. These components are usually soldered onto the board as the board provides mechanical support and a basic substrate.

PCBs can also be either single, double, or even multi layered depending on how many layers of copper it uses on top of its substrate layer. The use of either of the options depends on the functionality you need to extract from the PCB. These days, the degree of flexibility and capability that circuit boards commonly used possess far exceeds what used to be considered standard just a few years back. As any other technology, achieving what we know as a PCB today was a gradual process, one that took plenty of experimentation, failure, and success. Ultimately, the goal has been to create a manufacturing process for PCBs that allow us to incorporate and integrate maximum functionality onto the smallest of chips. The smaller and more functional the technology, the better.

Years 1900-1950

In the early 1900s, there was no common or widespread use of printed circuit boards. Instead, people used point to point construction to create large and bulky designs executed onto a chassis which was basically a wooden or metal base or frame. They would attach large insulators, regulators, and other components onto this frame and then connected to each other with soldered wires and connectors. While they did the work, they were slow, inefficient, unreliable, and extremely fragile, prone to breakdowns which would result in the loss and wastage of countless efforts and labor.

It wasn’t until 1903, when Albert Hanson filed a patent for a device that would use an insulating board paired with foil conductor arranged in multiple layers, that we actually started to move in the direction of printed circuit boards. The German conductor also showed how you could punch holes through the layers to connect them electrically. Subsequently, several scientists and leaders in the field of electronics and engineering began experimenting with the idea of further developing this concept. While there were significant efforts made to introduce new and improved electronic devices and appliances to the general market, the evolution of the circuit board faced some obstacles in the form of the world war and the Great Depression.

In the late 1936, an Austrian engineer, Paul Eisler, invented the printed circuit board concept using existing printing technologies.

Years 1950 – Today

Ultimately, as part of their effort to start using proximity fuses to participate in World War 2, the US government picked up this technology for their military purposes. As more and more work and development was done in this regard, it resulted in the introduction of the printed circuit board on a commercial basis by the middle of the 1950s.

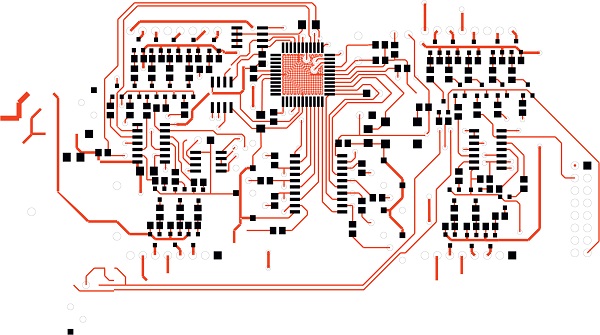

During this era, the substrates used to create a circuit board included the likes of resins and bakelite. What was a complicated process, the superior speeds and efficiency, as well as the significant reduction in the size of the board, is what encouraged inventors to pursue and invest in this tech. The pattern of the wires would be hand drawn onto the board and photographed onto a zinc plate which could then be used to print the electronic design. A copper foil would be used as a conducting material and the design would be etched on with acid resistant ink.

Through the 1960s and 70s, as we moved past the era of having to drill and punch holes and use wires to establish an interconnection between the various components on the circuit board, we instead began to focus our energies towards making the PCB smaller and smaller without compromising on the speed or efficiency of the circuit, if not improving it further. This lead to the popularity of using surface mount parts rather than components that went through holes by the 1980s. This helped improve functionality while cutting down on the size as well as the costs.

From there, the trend has continued to keep increasing the complexity of circuit boards. By the 1990s, multilayered PCBs had been introduced in the market and inventors began to realize the potential behind this piece of tech. PCBs became smaller and smaller and also more flexible as manufacturers started to use micro-via technology in order to produce PCBs using High Density Interconnects. This further enabled manufacturers to incorporate greater designs onto a smaller surface.

Now, with three dimensional printing in our hands, it is only understandable that the trend of producing complex and miniature designs on PCBs will continue to move in the upwards direction.