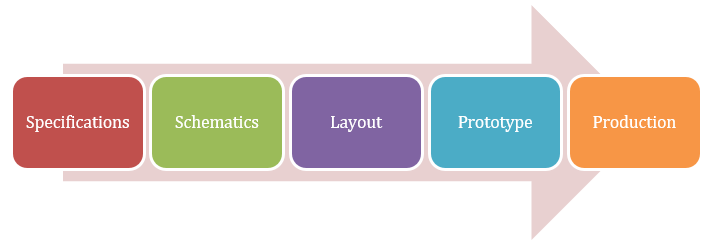

The Ultimate Guide to Electronic Design Process

24/04/2019, hardwarebee

This paper is about Electronic Design Process and will help you understand the steps you need to take to develop any electronic product from the idea phase all the way to mass production.

Specifications

To begin with, you need to define the product you are wishing to design and produce. You should capture all the requirements and the specifications in a single document. Subsequently, you will use this information to create a product proposal in which you will formally introduce your concept and elaborate on your idea to your colleagues, management or investors. In addition to the technical requirements and features, add also target product cost, size and schedule.

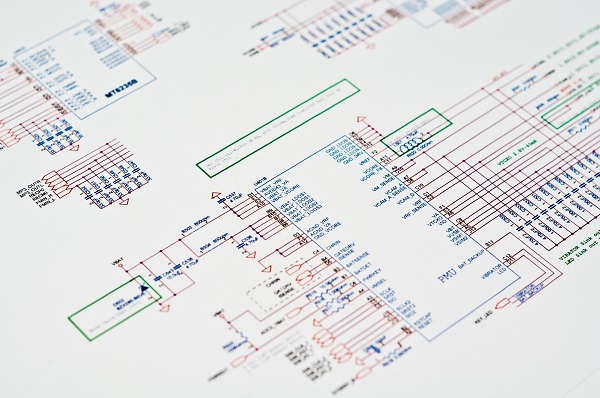

Schematic Capture

Once your specifications are locked and loaded and you are ready to proceed to the next step in the electronic design process, you now have to create the schematics for your product. Your schematics will consist of ICs, passive components (capacitors, resistors and inductors) and all the connectors you may need in your product. Schematic drawings are the very basis upon which the building of your product, so it is necessary that the schematic design is carefully thought out and meticulously planned down to the last detail.

Every mistake in the schematics will be costly after your produce your prototypes. Therefore, it’s recommended to go through a design review process – let other engineers review your work and provide feedback and suggestions.

Schematics are drawn in a computer software program, some of the programs provide also simulation capabilities – allowing you to simulate your design before you go to production. You can use the software to run simulations and conduct small tests side by side as you draw your schematic, making it an incredibly powerful and useful tool to help you find errors and mistake early in the design phase.

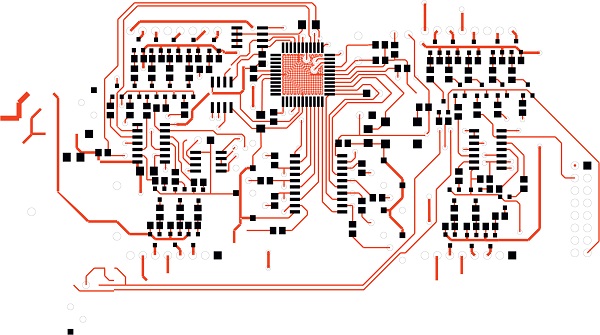

PCB Layout

The next step, after you are done designing your schematics, is to design the actual PCB, which is the printed circuit board. You first need to decide where to place every component and how they will be connected across the PCB. This can also be done automatically with the help of PCB layout tools.

After you are done designing your PCB as well, the software will run a design rule check to determine if there are any discrepancies or errors in the layout and the various specifications regarding the connections and placement of components.

When this step is completed successfully, the PCB layout program will generate all the necessary files for the next steps – PCB production and PCB assembly.

Prototype Production

The next step is to send out your files to PCB a manufacturer and have them build a prototype for you, so you can conduct the relevant tests in the relevant environment to assess its functionality and performance. If you do find any problems with the prototype, it is imperative that they be fixed before the design is sent for mass production.

The model or prototype should also be also used to review the cost of the components, the cost of the overall product, the appearance, as well as the function of the future product so that the needed changes or enhancements can be made as soon as possible.

Mass Production

This is the stage where you must collect all the documents and information that you possibly can which will enable manufacturing companies, third party or in house, to recreate your design and test it. An incomplete information and specifications portfolio will only lead to a waste of resources and investment on your part which is why it is advised that special care be taken to ensure that all the relevant data is available to the manufacturer and it’s of course, accurate.