The Brief Guide to PCB Design Flow

27/04/2019, hardwarebee

A PCB, or a Printed Circuit Board, is one of the most critical components in any electronic product because it is the element that connects all the ICs and passive components that comprises of an electronic product.

If a PCB is lacking one connection, the product will mostly likely not work.

Today, the process of designing and manufacturing PCBs is very robust and consists of a few sequential steps bases on a PC software.

This article is a general overview of the PCB designing process. Some engineers use more (or less) steps in the PCB design flow, but – essentially, all the various PCB design processes are based on the following steps:

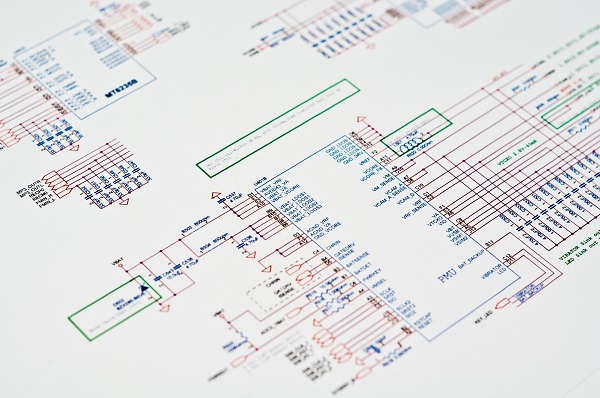

Drawing the Schematics

The very first step in the PCB design process is drawing the schematics of the circuit board. You can do so using a schematic capture tool that allows you to create schematics by entering your ICs, passives and connectors into the tool and then connecting all the necessary wires. You can also look into getting a software package that allows you to run simulations. This will let you to test the PCB’s functionality before the manufacturing process.

At the end of this step, the schematics are converted into a netlist file. A netlist file is basically a database that has taken your circuit diagram and condensed all the graphic information into a list of nets. Every net represents a wire on the PCB and its connection to the designated components.

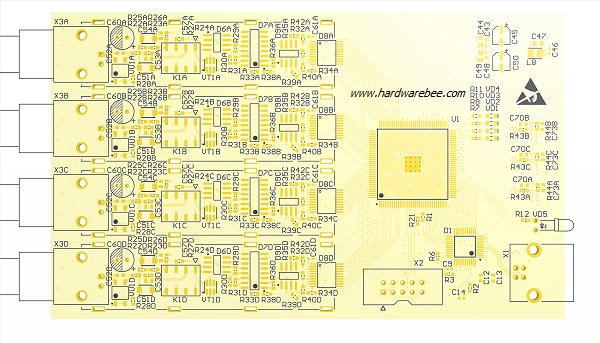

PCB Placement

The next step in the PCB design process is to decide about the components (ICs, passives, connectors, etc.) location across the PCB. You will be roughly arranging them on your board to determine that you have enough space and can accommodate the needed elements the way you want. After obtaining a rough placement, you can further look into detailing out the specifics regarding the orientation and the exact positions of each component depending on the number of nets, thermal consideration and other requirements your product may have (for example: antenna location or power supply input etc.).

The final placement will be fine-tuned in the routing phase.

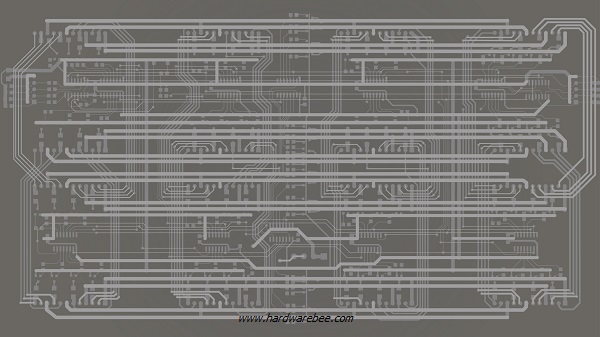

PCB Routing

The next step is to determine the route and paths that your interconnections will be taking to get from one pin to another or from one component to another. Routing is generally a time-consuming process as the software takes the information you provided and the netlist to map out the routes on the circuit board across the various layers that you have defined. Some of the nets should be short (for example: clock signals) or equal in length (for example: differential pairs) – you should begin your routing process with the high priority signals.

Design Rule Check

PCB layout software allows you to check whether your PCB can be manufacture by the PCB manufacturing company. Every manufacturing company has various design rules that they provide to PCB designers. The design rule check allows you to detect any discrepancies early on and correct any errors that may potentially cause you trouble in the PCB manufacturing phase. Such error could be: two ICs are too close to each other so that the assembly machine will not able to reach out and place on of them on the PCB.

At the end of this process, you will most likely have Gerber files, a standard format for files pertaining to PCBs, containing the visual information and the visual plots for your circuit. Not only do these files contain visual images, but also information regarding the drilling and assembly instructions.