What is Electronic Manufacturing Services (EMS)?

19/05/2021, hardwarebee

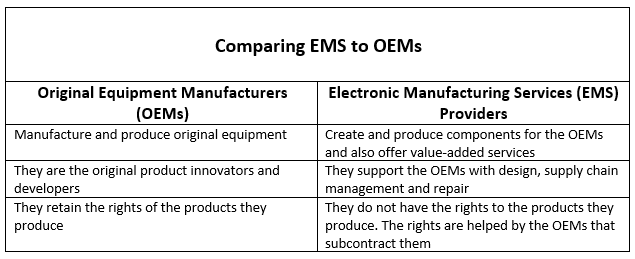

Electronic Manufacturing Services (EMS) refers to a group of companies or an overall industry that provides value added manufacturing and engineering services to Original Equipment Manufacturers (OEMs). EMS is also referred to as “contract manufacturing”.

By providing value-added manufacturing and engineering services to the OEMs, Electronic Manufacturing Services (EMS) allows the OEMs to maintain focus on the core activities of development and researching to increase operational efficiencies of their organization.

EMS companies offer a wide range of services in different areas including industrial products (like automation and robotics), electronic components (like semiconductors and conductors), and medical devices, and their services span manufacturing industries, government, and health care to consumers.

Characteristics of Electronic Manufacturing Services

Below are the main characteristics and features of Electronic manufacturing services companies:

Design for manufacturing

EMS always keeps the manufacturing process in mind when designing products. Whatever is designed must pass through manufacturing to generate the final products that meet the goals of the OEMs.

Good EMS understands the need for a product to easily move through manufacturing.

Use of advanced technologies

As technology evolves, there is a rise in the demand for complex electronic components that require novel features like higher component density, smaller pitches, precision placement, and multiple layers. As a result, manufactures are adopting more advanced, sophisticated, and innovative technological solutions to make the production process of these components more efficient.

Examples of the advanced technologies that have been adopted by most electronic manufacturing services include smart technology, the Internet of Things (IoT), automation, robotics, and artificial intelligence (AI).

It is estimated by the year 2030, robots will account for approximately 45% of the production in the manufacturing processes.

AI on the other hand enables EMS to automate and streamline the production of electronic components increasing efficiency, reducing cost, and maintaining high-quality standards.

Compliance with industry standards

Electronic manufacturing services companies are required to observe the most current industry standards for design and manufacturing to ensure that they provide the OEMs with components that meet the industry standards.

In addition to the industry standards, and EMS providers also comply with the specific standards set by the OEMs subcontracting it.

Restriction of Hazardous Substances (RoHS) compliance

Good electronic manufacturing services providers are always mindful of the environment. They comply with the Restriction of Hazardous Substances (RoHS) Regulations 2012 that restrict the use of specific hazardous substances in electrical and electronic components.

EMS providers help in ensuring that the design proposals are ROHS compliant.

Product testing

After producing components EMS providers thoroughly tests the components to ensure that they are highly functional and perform as expected.

Supply chain management

Electronic manufacturing service providers specialize in procuring raw materials and pooling together resources. In so doing they outsource components from different parts of the globe to ensure that they meet the needs of the OEMs that subcontract them. They also ensure that they meet the specific needs of the OEMs especially concerning the contract requirements, sourcing restrictions, and preferred vendors among others.

Offer fulfillment services

EMS companies also provide offer fulfillment services like troubleshooting faulty components and making the required repairs in case the products they produce for the OEMs have faults.

What is an example of an Electronic Manufacturing Services?

Electronic Manufacturing Services companies offer services that cut across design, manufacturing, testing to distribution.

A good example of an electronic manufacturing service provider is BTG labs, which was a cutting-edge materials science-based technology company in Ohio, the USA that offered manufacturers adhesive quality control. It offers support to manufacturers to help them optimize surface preparation and diagnose the main reasons for adhesion failures.

For example, BTG labs services help electronics manufacturers to build components that can resistant to elemental threats. The BGT labs instruments can be used to reveal the cleanliness level of the surface of a circuit board to create a successful bond between the circuit board and the conformal coating. In so doing the Original manufacturer of the circuit board would reduce waste and failure resulting from the unsuccessful coating.

History of Electronic Manufacturing Services (EMS)

The first EMS provider was called Solectron Corporation and it was founded in 1977 to provide outsourced services to original equipment manufacturers. The founders, Roy Kusumoto and Prabhat Jain spotted a growing need for printed circuit board assembly (PCBA) by the growing number of electronics companies in California’s Silicon Valley and established Solectron to quickly and efficiently design and manufacture products and also provide after-sales services for the various OEMs.

The services of Solectron included designing and manufacturing mainframe computers, point-of-sale systems, PCs, servers, workstations, storage systems, optical networking equipment, core and edge Ethernet switches, core and edge routers, NICs, DSL, cable broadband equipment, cellular infrastructure equipment, IP PBX, Voice-over-Internet Protocol (VoIP) equipment, wireless and wireline Broadband infrastructure, DSLAMS, car audio and navigation systems, ABS and airbag control modules, engine and ignition control modules, automobile HVAC units, telematics, automotive body electronics, MP3 players, GPS, mobile handsets, video game systems, personal video recorders, PDAs, digital set-top boxes, and test and measurement instruments, process automation equipment, semiconductor fabrication equipment controls and security systems, among others. It also offered offer fulfillment services that included warranty management, forward and reverse logistics, asset recovery and remarketing, and repair and return.

Later on, other EMS companies like SCI and Avex were established. However, the development of Surface Mount Technology (SMT) on printed circuit boards (PCB) in the early 1990s made it hard for the EMS companies since most OEMs installed SMT lines in their manufacturing process thus taking up most of the work that was being done by the EMS companies.

In the mid-1990s, most OEMs found it economically advantageous to outsource PCB assembly (PCBA) from the EMS providers to allow the OEMs to concentrate on other manufacturing activities without compromising the quality of circuit boards.

By the early 2000s, most of the OEMs had sold their PCBA lines to the EMS providers.

Solectron was acquired by Flextronics International, Ltd in 2007.

Advantages of Electronic Manufacturing Services

EMS offers the following benefits to the original equipment manufacturers (OEMs):

- Reducing costs. By outsourcing EMS services, OEMs reduce capital investments.

- It mitigates and reduces the risks involved in producing the electronic components since the EMS handles everything from design, manufacturing, testing, distribution to after-sale services like repair and return and warranty management.

- EMS improves speed to market. By outsourcing the EMS services, OEMs can work on other areas involved in manufacturing/producing their equipment and thus ensure that the equipment reaches the market quickly.

- EMS providers offer greater agility and improve productivity.

Disadvantages of Electronic Manufacturing Services

- Electronic manufacturing services create a risk of your intellectual property being stolen since by outsourcing for the EMS services you provide the EMS provider with access to your intellectual property.

- If not properly managed, OEMs could run into a communication gap once they subcontract an EMS provider and that may lead to a variety of problems like unrealistic timelines, improper internal communication, and lack of a transition plan.

- There is also the risk of losing control of the manufacturing process there is no constant supervision.

Trends in the Electronic Manufacturing Services Industry

The electronic manufacturing services industry has seen tremendous growth which can be attributed to several factors that include:

- A surge in the demand for automotive electronics attributed to the increased need for safety systems.

- Increasing demand for consumer electronics in both developing and developing countries around the world.

- Rapid growth in mobile devices technology. By 2020, over 5.4 billion people around the world owned a mobile phone.

Top 10 Electronic Manufacturing Services Leaders

- Flex Ltd

- Jabil Inc

- Hon Hai Precision Industry Co., Ltd., (trading as Foxconn Technology Group)

- Pegatron Corporation

- Wistron Corporation

- Celestica Inc.

- Compal Electronics

- Quanta Computer Incorporated

- Funai Electric CO., LTD

- Hosiden

EMS Today & Future

Today, there are very many EMS providers across the globe that have been established to need the growing demand for electronics components and outsourced electronics manufacturing services by OEMs.

According to market research, the EMS industry is forecast to be worth $725 billion by 2025 at a compound annual growth rate (CAGR) of 7.5%. There is a growing demand for innovative technological advancements and innovation that most EMS providers can capitalize on.

However, EMS providers will have to provide more industry expertise and experience to meet the rising demands amidst the challenges of the need for robust product lifecycle management systems, increasing labor costs, global competition, compliance and traceability, and the huge investments required for the infrastructure and support systems to manage complex, and highly controlled markets like aerospace, defense and medical.