What’s Inside an FPGA

17/12/2018, hardwarebee

FPGA (Field Programmable Gate Array) is a very popular technology used in a range of applications and by many engineers. Looking at an FPGA with bare eyes not always reviling what inside the package and how it’s constructed. The purpose of this paper is to describe the internal structure of a typical BGA package and the different elements that consist a BGA package.

FPGA is most likely to be packaged in a BGA (Ball Grid Array) package type as showed in the below figure. BGA is a very common package type that used widely in various applications. The package balls are clearly on the bottom size of the FPGA and they are connected internally to the FPGA silicon die.

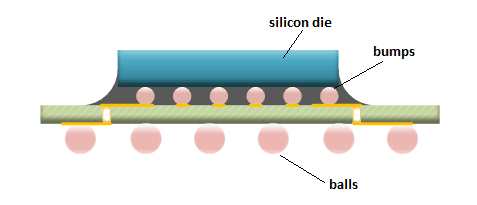

In fact, the package seen above is called Flip Chip Ball Grid Array (FCBGA), and it’s based internally on bumping technology (rather than wirebond technology which is used for smaller size package types). The following figure shows a side view of a BGA package (excluding the top lid)

Picture courtesy of AnySilicon.com

Silicon die – This is the FPGA silicon wafer that has been sawed into a single die. The wafer is produced in a wafer foundry.

Bumps – Those are tiny solder balls connecting the silicon die to the BGA substrate. bumps are distributed across the entire the chip and not only located on the die edge, pads can be placed all over the surface of the die. This allows designers to place more pads per area, reduce the chip size, and optimize for signal integrity.

BGA Substrate – This is the internal PCB that fans out the bumps signals into a larger area and connecting those signals to the balls. The substrate is a small PCB located inside the package and is very similar to other PCBs. The main difference is the BGA substrate size, via, routing are much smaller than most of the PCBs you have seen before.

Balls – Those are the solder balls that connect that BGA package to the target application PCB.

Lid – Is the top surface that is commonly used for company logo and part number is actually used for protecting the die from physical damages and also to dissipate the heat generated by the silicon die.