This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Electronic Board Assembly

Understanding Electronic Board Assembly: A Comprehensive Guide

Electronic Board Assembly (EBA) is a critical process in the manufacturing of electronic devices. It involves the assembly of electronic components onto printed circuit boards (PCBs) to create functional electronic products. This article delves into the intricacies of electronic board assembly, covering its processes, technologies, benefits, and future trends.

What is Electronic Board Assembly?

Electronic Board Assembly refers to the process of assembling electronic components onto a PCB. This process is essential for creating devices such as smartphones, computers, and various consumer electronics. The assembly can be done manually or through automated processes, depending on the complexity and volume of production.

The Importance of Electronic Board Assembly

Electronic Board Assembly is vital for several reasons:

- Quality Control: Proper assembly ensures that electronic devices function correctly and meet quality standards.

- Cost Efficiency: Streamlined assembly processes can reduce production costs and time.

- Scalability: EBA allows manufacturers to scale production according to market demand.

- Innovation: Advances in assembly technology enable the development of more complex and compact electronic devices.

The Electronic Board Assembly Process

The EBA process can be broken down into several key stages:

1. Design and Prototyping

The first step in EBA is designing the PCB layout using computer-aided design (CAD) software. Engineers create a schematic that outlines the connections between components. Prototyping is then conducted to test the design before mass production.

2. Sourcing Components

Once the design is finalized, manufacturers source the necessary electronic components. This includes resistors, capacitors, integrated circuits, and connectors. Sourcing quality components is crucial for the overall performance of the final product.

3. PCB Fabrication

After sourcing components, the next step is PCB fabrication. This involves creating the physical board from materials such as fiberglass or epoxy resin. The fabrication process includes etching, drilling, and applying solder mask and silkscreen layers.

4. Component Placement

In this stage, components are placed onto the PCB. This can be done manually or using automated pick-and-place machines. Automated machines are preferred for high-volume production due to their speed and accuracy.

5. Soldering

Soldering is the process of joining electronic components to the PCB. There are several soldering methods, including:

- Wave Soldering: A method where the PCB passes over a wave of molten solder.

- Reflow Soldering: Used primarily for surface-mounted components, where solder paste is applied and then heated to melt the solder.

- Hand Soldering: A manual process used for small batches or repairs.

6. Inspection and Testing

After soldering, the assembled boards undergo inspection and testing to ensure they meet quality standards. This can include visual inspections, automated optical inspection (AOI), and functional testing.

7. Final Assembly and Packaging

Once the boards pass inspection, they are integrated into the final product. This may involve additional assembly steps, such as housing the PCB in a casing and adding connectors. Finally, the products are packaged for shipment.

Technologies in Electronic Board Assembly

Several technologies play a crucial role in the electronic board assembly process:

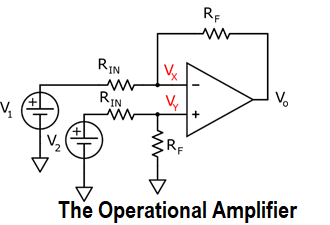

1. Surface Mount Technology (SMT)

SMT is a method where components are mounted directly onto the surface of PCBs. This technology allows for smaller and more compact designs, making it ideal for modern electronic devices.

2. Through-Hole Technology (THT)

THT involves inserting component leads through holes in the PCB and soldering them on the opposite side. While less common in new designs, THT is still used for certain applications requiring robust connections.

3. Automated Assembly Equipment

Automated pick-and-place machines, soldering robots, and inspection systems have revolutionized EBA. These machines enhance precision, speed, and efficiency, reducing the likelihood of human error.

4. 3D Printing

3D printing technology is increasingly being used in EBA for rapid prototyping and even for creating certain components. This technology allows for greater design flexibility and faster turnaround times.

Benefits of Electronic Board Assembly

Investing in electronic board assembly offers numerous advantages:

1. Enhanced Efficiency

Automated assembly processes significantly reduce production time, allowing manufacturers to meet market demands more effectively.

2. Improved Quality

With advanced inspection technologies, manufacturers can ensure higher quality standards, reducing the risk of defects and failures in the final product.

3. Cost Savings

Streamlined processes and reduced labor costs lead to overall cost savings, making it more feasible for companies to produce high-quality electronic devices.

4. Flexibility and Scalability

Modern EBA technologies allow manufacturers to quickly adapt to changes in design or production volume, providing a competitive edge in the market.

Challenges in Electronic Board Assembly

Despite its advantages, EBA also faces several challenges:

1. Component Shortages

The global semiconductor shortage has impacted the availability of essential components, leading to delays in production and increased costs.

2. Complexity of Designs

As electronic devices become more complex, the assembly process must adapt to accommodate intricate designs, which can complicate manufacturing.

3. Quality Assurance

Ensuring consistent quality across large production runs can be challenging, requiring robust inspection and testing protocols.

Future Trends in Electronic Board Assembly

The future of electronic board assembly is poised for significant advancements:

1. Increased Automation

As technology continues to evolve, the trend towards greater automation in EBA will likely increase, enhancing efficiency and reducing costs.

2. Smart Manufacturing

Integrating IoT and AI into the assembly process will enable real-time monitoring and predictive maintenance, further improving efficiency and quality.

3. Sustainable Practices

With growing environmental concerns, manufacturers are increasingly focusing on sustainable practices, such as reducing waste and using eco-friendly materials.

Conclusion

Electronic Board Assembly is a fundamental aspect of modern electronics manufacturing. Understanding its processes, technologies, and challenges is essential for anyone involved in the industry. As technology continues to advance, EBA will play a crucial role in shaping the future of electronic devices, driving innovation, and meeting the demands of an ever-evolving market.

FAQs about Electronic Board Assembly

1. What is the difference between SMT and THT?

Surface Mount Technology (SMT) involves mounting components directly onto the surface of the PCB, while Through-Hole Technology (THT) requires inserting component leads through holes in the PCB. SMT is generally preferred for modern designs due to its compactness.

2. How does automation impact electronic board assembly?

Automation enhances the efficiency, speed, and accuracy of the assembly process, reducing labor costs and minimizing human error.

3. What are the common inspection methods used in EBA?

Common inspection methods include visual inspections, automated optical inspection (AOI), and functional testing to ensure quality and performance standards are met.

4. Why is quality control important in electronic board assembly?

Quality control is crucial to ensure that electronic devices function correctly and reliably, reducing the risk of defects and failures in the final product.

5. What are the future trends in electronic board assembly?

Future trends include increased automation, smart manufacturing practices, and a focus on sustainability in the assembly process.