This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Printed Circuit Board Turnkey

Understanding Printed Circuit Board Turnkey Solutions

In the rapidly evolving world of electronics, the demand for efficient and reliable manufacturing processes has never been higher. One of the most significant advancements in this field is the concept of Printed Circuit Board (PCB) Turnkey solutions. This article delves into what PCB turnkey solutions are, their benefits, the process involved, and why they are essential for modern electronics manufacturing.

What is a Printed Circuit Board (PCB)?

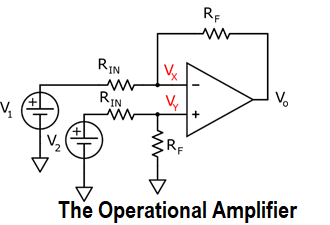

A Printed Circuit Board (PCB) is a crucial component in electronic devices, serving as the backbone that connects various electronic components. PCBs are made from insulating materials, typically fiberglass, and are embedded with conductive pathways that allow electricity to flow between components. They come in various forms, including single-sided, double-sided, and multi-layered boards, each serving different applications.

Defining Turnkey Solutions

The term turnkey refers to a service or product that is ready for immediate use upon delivery. In the context of PCB manufacturing, a turnkey solution encompasses the entire process from design to production, assembly, and testing. This means that the manufacturer takes full responsibility for the entire lifecycle of the PCB, providing a seamless experience for the client.

Components of PCB Turnkey Solutions

PCB turnkey solutions typically include several key components:

- Design Services: This involves creating the schematic and layout of the PCB, ensuring that it meets the required specifications and standards.

- Prototyping: Before mass production, prototypes are created to test the design and functionality of the PCB.

- Manufacturing: This includes the actual production of the PCB, which involves etching, drilling, and layering processes.

- Assembly: Components are soldered onto the PCB, either through manual or automated processes.

- Testing: Rigorous testing is conducted to ensure that the PCB functions correctly and meets quality standards.

- Logistics: Finally, the completed PCBs are packaged and shipped to the client.

Benefits of PCB Turnkey Solutions

Opting for PCB turnkey solutions offers numerous advantages:

1. Cost-Effectiveness

By consolidating multiple processes under one provider, companies can reduce costs associated with managing multiple vendors. This streamlined approach minimizes overhead and can lead to significant savings.

2. Time Efficiency

Turnkey solutions significantly reduce the time from design to production. With a single point of contact, communication is streamlined, and project timelines are shortened.

3. Quality Assurance

Turnkey providers often have established quality control processes in place. This ensures that every stage of production meets high standards, resulting in a reliable final product.

4. Simplified Communication

Working with a single provider simplifies communication, reducing the chances of misunderstandings and errors that can occur when multiple vendors are involved.

5. Expertise and Experience

Turnkey providers typically have extensive experience in PCB manufacturing and assembly. Their expertise can lead to better design choices and more efficient production processes.

The PCB Turnkey Process

The PCB turnkey process can be broken down into several stages:

1. Initial Consultation

The process begins with an initial consultation where the client discusses their requirements, including design specifications, budget, and timeline.

2. Design and Prototyping

Once the requirements are established, the design team creates a schematic and layout for the PCB. Prototypes are then produced to test the design.

3. Manufacturing

After the prototype is approved, the manufacturing process begins. This includes the fabrication of the PCB, where layers are created, and conductive pathways are etched.

4. Assembly

Once the PCBs are manufactured, components are assembled onto the boards. This can be done through surface mount technology (SMT) or through-hole technology, depending on the design.

5. Testing and Quality Control

After assembly, the PCBs undergo rigorous testing to ensure functionality. This may include electrical testing, visual inspections, and functional testing.

6. Packaging and Delivery

Finally, the completed PCBs are packaged securely and shipped to the client, ready for integration into their products.

Choosing the Right PCB Turnkey Provider

When selecting a PCB turnkey provider, consider the following factors:

1. Experience and Reputation

Look for a provider with a proven track record in the industry. Check reviews and testimonials to gauge their reputation.

2. Capabilities

Ensure that the provider has the necessary capabilities to meet your specific requirements, including design, manufacturing, and testing.

3. Quality Standards

Inquire about the quality control processes in place. A reputable provider should adhere to industry standards such as ISO 9001.

4. Communication

Effective communication is crucial for a successful partnership. Choose a provider that is responsive and transparent throughout the process.

5. Cost

While cost should not be the only factor, it is essential to ensure that the pricing is competitive and aligns with your budget.

Applications of PCB Turnkey Solutions

PCB turnkey solutions are utilized across various industries, including:

1. Consumer Electronics

From smartphones to home appliances, PCBs are integral to consumer electronics, making turnkey solutions essential for efficient production.

2. Automotive

Modern vehicles rely heavily on PCBs for various functions, including navigation systems, engine control units, and safety features.

3. Medical Devices

In the medical field, PCBs are used in diagnostic equipment, monitoring devices, and therapeutic machines, where reliability is paramount.

4. Industrial Equipment

PCBs are also found in industrial machinery, automation systems, and control panels, highlighting the need for robust manufacturing processes.

5. Telecommunications

Telecommunication devices, including routers and switches, rely on PCBs for connectivity and performance, making turnkey solutions vital for timely production.

Future Trends in PCB Turnkey Solutions

The PCB industry is continuously evolving, and several trends are shaping the future of turnkey solutions:

1. Miniaturization

As electronic devices become smaller, the demand for compact and efficient PCBs is increasing. Turnkey providers are adapting to these needs by developing advanced manufacturing techniques.

2. Advanced Materials

New materials, such as flexible PCBs and high-frequency laminates, are being integrated into designs, requiring turnkey providers to stay updated with the latest technologies.

3. Automation and AI

Automation and artificial intelligence are streamlining the manufacturing process, improving efficiency, and reducing errors in PCB production.

4. Sustainability

With growing environmental concerns, many PCB manufacturers are adopting sustainable practices, including waste reduction and the use of eco-friendly materials.

5. Internet of Things (IoT)

The rise of IoT devices is driving demand for PCBs that can support connectivity and data processing, pushing turnkey providers to innovate continuously.

Conclusion

In conclusion, PCB turnkey solutions offer a comprehensive approach to PCB manufacturing, providing numerous benefits such as cost savings, time efficiency, and quality assurance. As the electronics industry continues to grow and evolve, the importance of reliable and efficient PCB manufacturing processes will only increase. By understanding the components, benefits, and future trends of PCB turnkey solutions, businesses can make informed decisions that enhance their production capabilities and drive innovation.

Whether you are a startup looking to develop your first product or an established company seeking to streamline your manufacturing process, partnering with a reputable PCB turnkey provider can be a game-changer. Embrace the future of electronics manufacturing with PCB turnkey solutions and stay ahead in this competitive landscape.