The Ultimate Guide to PWM Controller

03/06/2025, hardwarebee

Pulse width modulation (PWM) is a technique used to encode information onto a carrier wave by modulating the width of pulses. At its core lies the concept of duty cycle, which crucially influences how efficiently power is utilized and distributed. This article delves into the salient features of PWM controllers, their diverse applications in industries like solar energy, automotive, and telecommunications, and the cutting-edge technology that makes them indispensable.

The guide you’re about to explore will cover everything from the importance of PWM signals to the challenges in designing systems that incorporate these controllers. We’ll also draw comparisons between PWM and other types of controllers, provide insights on high-performance PWM solutions, and offer practical advice on selecting the perfect PWM controller IC for your needs. Join us as we unravel the intricacies of PWM controllers and their significance in modern electronic systems.

Understanding Pulse Width Modulation (PWM)

Pulse Width Modulation, or PWM, is a technique used to control the power delivered to electrical devices. It works by switching the power on and off rapidly. This helps to adjust the flow of electrical energy in systems such as solar charge controllers, fan controllers, and motor speed controllers. The method is popular in managing devices where precise control is needed without losing efficiency. PWM controllers are often used for controlling DC motor speed and fan speed or adjusting the brightness of lights. They play a vital role in electrical circuits by providing a way to control devices without the complications of complex systems.

Basic Concepts of PWM

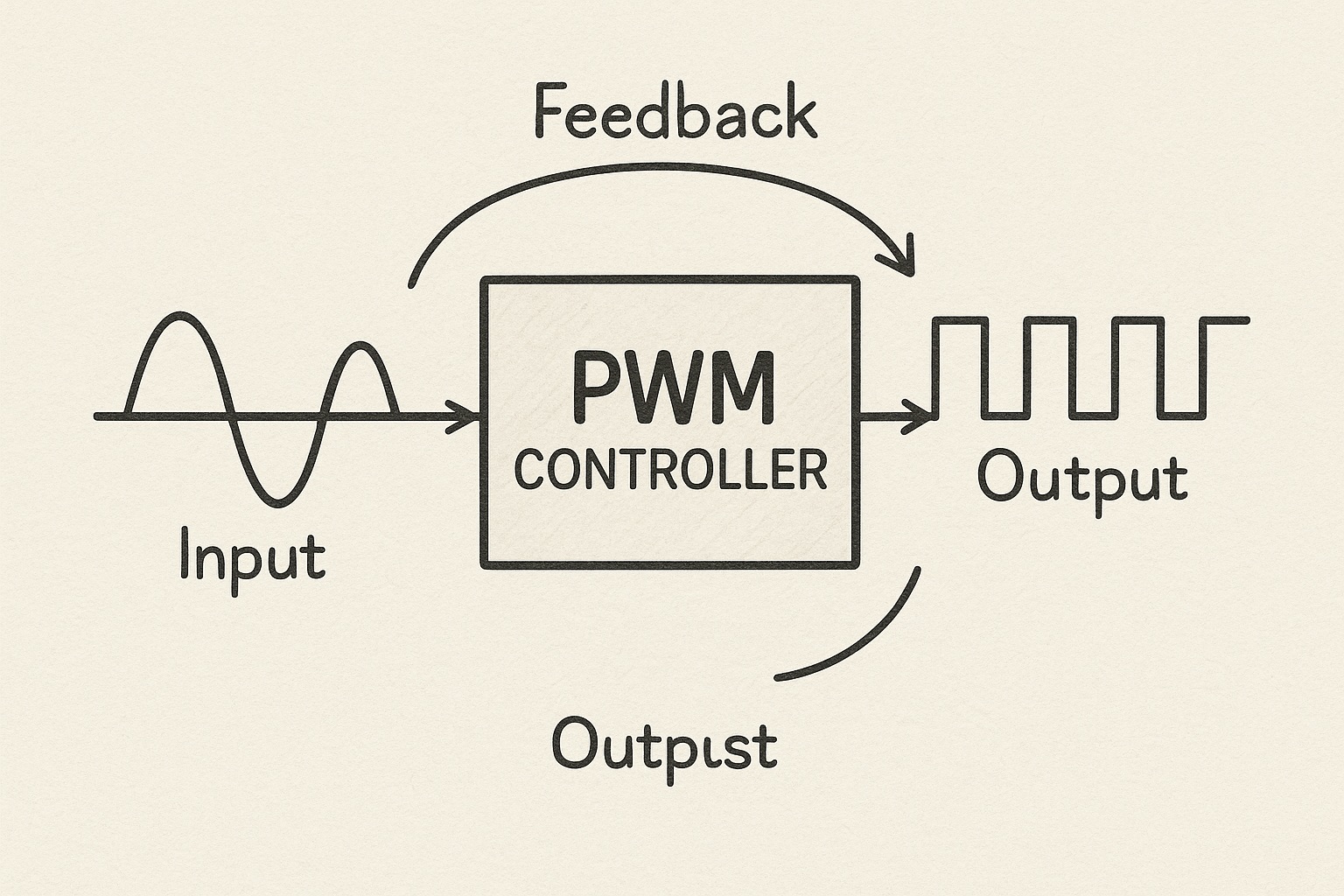

PWM is a fundamental concept in the control of electronic devices. It works by varying the width of the pulses in a signal to control the power supplied to a load. The PWM signal switches between ON and OFF states, adjusting how long the power is on during each cycle. This method is useful because it allows for efficient control of the average voltage sent to a device. For example, a PWM solar controller can manage the voltage from solar panels to optimize the charging of batteries. By altering the frequency and width of the pulses, PWM can maintain consistent control, ensuring that devices operate smoothly and efficiently. This type of control circuit is essential for various industrial applications.

Importance of Duty Cycle in PWM

The duty cycle is a key aspect of PWM that determines the effectiveness of the signal. By definition, the duty cycle refers to the percentage of one period in which a signal is active. A high duty cycle means the signal is active for a greater portion of the time, delivering more power. Conversely, a low duty cycle reduces power delivery. Understanding and adjusting the duty cycle is crucial for applications like fan speed controllers and DC motor speed controller switches. For instance, in a PWM fan controller, altering the duty cycle changes the speed at which the fan operates, allowing for precise temperature control. Proper management of the duty cycle in systems ensures devices function at their best, optimizing performance and energy efficiency.

Applications of PWM Controllers

Pulse-width modulation (PWM) controllers are essential components in many modern technologies. These devices control electrical energy by switching it on and off at precise intervals. This allows for efficient and accurate control of various processes. From industrial applications to consumer electronics, PWM controllers improve performance and energy efficiency. They play a critical role in managing power for things like solar panels, motors, and electronic devices.

DC Motor Speed Control

PWM controllers are widely used to control the speed of DC motors by adjusting the voltage applied to the motor terminals. A PWM DC Motor Speed Controller Switch precisely manages how much power is delivered, altering motor speed smoothly. The technology is ideal for applications requiring variable motor speeds, such as in robotics or conveyor systems. By modulating the pulse width, the controller maintains desired speeds even under varying load conditions.

Solar Charge Controllers

In solar power systems, PWM controllers manage the voltage between solar panels and batteries. They ensure that the solar panels operate at an optimal voltage and protect batteries from overcharging. Solar Charge Controllers adjust the current based on sunlight availability and battery conditions. Devices like the 10A 12V 24V PWM Solar Controller are common in residential and small-scale solar applications.

Power Management in Electric Vehicles

PWMs play a crucial role in electric vehicles (EVs) by optimizing battery usage and improving energy efficiency. They regulate the delivery of electrical power to different components, such as the motor and auxiliary systems. By precisely controlling power flow, they enhance the EV’s range and performance. This PWM application helps in maintaining a balance between power supply and demand, offering a smooth driving experience.

Usage in Telecom and Servers

Telecom and server industries rely on PWM controllers for effective power management. PWM Fan Controllers adjust fan speed based on the device’s temperature, optimizing cooling while reducing energy use. This ensures that servers and telecom equipment run smoothly and efficiently. Implementing PWM controllers in these systems enhances reliability and minimizes power consumption.

PWM in Solar Inverters

Solar inverters use PWM technology to convert the DC power from solar panels into AC power for household or grid use. PWM inverters are efficient and cost-effective, making them popular in both residential and commercial solar installations. The PWM signal generated by the inverter synchronizes with the grid frequency, providing stable power output. This application of PWM is vital for integrating renewable energy sources into existing power systems.

Key Features of PWM Controllers

Pulse Width Modulation (PWM) controllers play a crucial role in various electronic devices and systems. They are widely used to manage the power supplied to different components, ensuring efficiency and precision. PWM controllers work by regulating the voltage and current in electrical circuits. This makes them ideal for applications such as solar charge controllers, DC motor speed control, and fan controllers. They serve both industrial applications and everyday devices by controlling power with high accuracy. This allows them to handle diverse tasks from adjusting fan speed in a computer to optimizing battery voltage in solar panels.

Efficiency and Power Density

The efficiency and power density of PWM controllers are critical for their success in various applications. By adjusting the PWM signal, these controllers minimize power loss and increase the efficiency of electrical energy use. High-performance PWM controllers are essential in optimizing the power output, which is particularly beneficial in solar charge controllers and DC motor speed controllers. With enhanced efficiency, devices consume less energy, leading to longer battery life and reduced operational costs. Furthermore, PWM controllers with high power density are compact, saving valuable space in electrical circuits while providing robust control over input voltage and other critical parameters.

EMI Reduction Techniques

Electromagnetic interference (EMI) can disrupt the performance of electronic devices. PWM controllers incorporate several EMI reduction techniques to maintain the integrity of their operations. One effective method is the use of control circuits that reduce switching noise during operation. These circuits keep the PWM signal stable, preventing unwanted disruptions. Another technique involves filtering, which cleanses the electrical output to reduce any interference with neighboring components. In industrial applications, minimizing EMI is crucial to ensuring safety and reliability. By integrating these advanced techniques, PWM controllers maintain high performance while reducing the risks associated with electromagnetic interference. This makes them invaluable in environments that demand precision and reliability.

Designing with PWM Controllers

Designing with PWM controllers involves understanding various components like AC and DC motor speed controllers and voltage regulators. PWM, or pulse-width modulation, is a technique used to regulate the power sent to electrical devices. It works by switching the power on and off at a rapid pace, thus providing an average control effect. PWM controllers are essential in solar charge controllers, dimmer power controllers, and fan speed control systems. They are used across different voltage levels, such as 12V or 24V systems, to maximize efficiency and performance. PWM controllers are popular in industrial applications due to their ability to handle a range of input voltages and ensure precise control of electrical energy.

Creating PWM Signals

Creating PWM signals is a crucial aspect of designing PWM controllers. It involves generating a sequence of pulses of varying widths, which determines the amount of power delivered to a load. For example, in a solar charge controller, PWM signals are used to regulate the charge going into a battery. To create these signals, a control circuit utilizes components like timers and oscillators.

PWM signals are widely used in controlling the speed of motors, such as DC motor speed controllers and fan controllers. In these applications, adjusting the width of the pulses alters the effective voltage applied to the motor, allowing for precise control of speed. This method makes PWM a preferred choice in scenarios that require efficient and stable power management.

Challenges in PCB Design for PWM Systems

PCB design for PWM systems presents unique challenges due to the high-frequency switching involved. This can lead to electromagnetic interference (EMI) if not handled properly. Designing an efficient and effective PCB layout is essential to minimize noise and ensure optimal performance.

One critical aspect is the placement of components within the control circuit. Proper placement helps reduce interference and enhances the stability of the PWM signal. Moreover, selecting appropriate copper traces and grounding techniques is vital in managing heat dissipation in high-performance PWM controllers. This ensures that the system can handle the demands of industrial applications without overheating or becoming unstable.

Another challenge is maintaining signal integrity. This involves using appropriate materials and shielding techniques to prevent signal loss or distortion. As technology advances, these design challenges become more complex, requiring engineers to stay updated with the latest techniques in PCB design for PWM systems to maintain efficiency and reliability in electrical circuits.

Differentiating PWM from Other Controllers

Pulse-width modulation (PWM) controllers are a key component in managing electrical energy across various applications. Unlike other controllers, PWM controllers can efficiently regulate the flow of power. They adjust the amount of energy sent to a device by turning the power on and off at high speed, rather than delivering a continuous flow. This method not only conserves energy but also reduces heat generation. PWM controllers are commonly used in fan controllers, DC motor speed controllers, and solar charge controllers. Their ability to maintain precise control makes them a popular choice in fields that require efficiency and longevity, outweighing many traditional methods.

PWM vs. MPPT Charge Controllers

When it comes to solar energy, choosing between PWM and MPPT (Maximum Power Point Tracking) charge controllers is crucial. PWM solar controllers connect solar panels directly to the battery voltage. This direct connection helps to maintain battery health but isn’t as efficient with high-voltage panels. Meanwhile, MPPT controllers optimize the energy harvest by matching the panel’s output to the battery’s needs. This optimization allows MPPT controllers to increase efficiency by up to 30%. Therefore, if cost-effectiveness and simplicity are priorities, PWM controllers are appealing. However, MPPT controllers take the lead in performance, especially in larger installations.

PWM for Fan Speed Control vs. Traditional Methods

PWM fan controllers offer a modern alternative to traditional fan speed controls. With PWM, fans receive rapid pulses of voltage, which allow for precise speed regulation. Traditional methods often rely on variable resistors to adjust speed, leading to wasted energy in the form of heat. PWM controllers, by contrast, send pulses that adjust fan speed without generating excess heat. This reduces energy consumption while extending fan life. In both industrial applications and household settings, PWM fan controllers ensure improved efficiency and quieter operation. As such, they are often seen as a superior choice to traditional methods, especially for those wanting control without energy waste.

High-Performance PWM Controllers

High-performance PWM controllers are essential in regulating electrical energy by adjusting the voltage sent to devices. These controllers are crucial for managing synchronous operations between devices like solar panels, motors, and other electrical circuits. They play a significant role in various applications, ensuring devices perform as required, providing efficiency, and maintaining system stability. By using pulse-width modulation, these controllers adjust the width of pulses in a PWM signal, optimizing the performance of connected devices.

Automotive-Grade PWM Controllers

Automotive-grade PWM controllers are engineered specifically to meet the rigorous demands of vehicular environments. They ensure that components like motors and fans operate efficiently under varying voltage conditions that vehicles face. These controllers help manage the electrical current for devices such as DC Motor Speed Controllers and fan controllers. They must endure high temperatures, vibrations, and other challenging conditions found in automotive settings. By using these controllers, vehicles can achieve improved energy efficiency and performance.

Multitopology PWM Controllers

Multitopology PWM controllers are designed to be versatile. They support multiple types of electrical circuit arrangements, making them adaptable for different industrial applications. This flexibility allows them to be used in both AC and DC systems. The controllers can switch between topologies like buck, boost, and buck-boost modes. This feature helps in efficiently managing different input voltages and load conditions. As a result, multitopology PWM controllers are ideal for applications where varied power requirements are common, such as in universal fan controllers and voltage regulators.

Considerations for Choosing PWM Controller IC

When selecting a PWM Controller IC for your project, it’s crucial to weigh several factors to ensure it meets your requirements. These controllers are essential for regulating electrical devices, making them vital in applications like solar panels, motors, and fan controllers. Understanding your specific needs, such as input voltage and the type of load you’ll control, helps in choosing the right one. High-performance PWM controllers are often required in industrial applications where precise electrical energy management is key. Moreover, the operating environment and system design constraints like size and power efficiency can influence your decision. By carefully evaluating these elements, you’ll ensure optimal performance and efficiency in your application.

What is a PWM Controller IC

A PWM (Pulse Width Modulation) Controller IC is an integrated circuit that regulates the power supplied to electrical loads. It works by switching the power on and off rapidly to control the amount of energy a device receives. This method is efficient for managing electrical devices, from small gadgets to large motors. PWM is widely used because it efficiently manages battery voltage and system power consumption. By altering the duty cycle—the proportion of on versus off time—it effectively changes the average voltage seen by the load, thus controlling its operation. This versatility makes PWM controllers a staple in many modern electronic applications.

How to Select the Right PWM Controller for Your Application

Selecting the right PWM controller involves understanding your application’s specific needs. First, consider the voltage requirements. Whether you’re working with 12V, 24V, or higher, make sure the controller can handle your input voltage. Next, identify the type of load, such as a DC motor speed controller or a fan controller, to ensure compatibility. Pay attention to the controller’s current capacity; if your application demands high power, you might need a 10A controller. Also, consider additional features like protection against overcurrent or thermal shutdown, which can safeguard your circuits. By aligning these factors with your project needs, you’ll choose a PWM controller that enhances performance and reliability.

Balancing Size and Performance in System Design

When designing a system, balancing size and performance is crucial, especially when dealing with PWM controllers. Compact systems might seem appealing, but ensuring that the controller’s capabilities aren’t compromised is essential. Smaller PWM controllers are useful when space is limited, like in portable devices. However, for industrial applications that require robust processing, performance should never be sacrificed for size. Engineers often aim to achieve the optimum balance by selecting controllers that offer high efficiency in a compact form factor. Evaluating your application’s specific needs helps in deciding whether to prioritize size or performance, or to find a middle ground.

Benefits of PWM Controller ICs

PWM controller ICs offer numerous advantages that make them popular in various applications. One key benefit is their efficiency in managing electrical energy. By adjusting the PWM signal, they maintain optimal performance with minimal power loss, which is crucial for battery-powered devices. They also allow precise control of motor speeds and light levels, making them ideal for both AC and DC motor speed controller applications. Additionally, their ability to smooth out voltage variations helps in maintaining device stability and extending operational life. The versatility and efficiency of PWM controllers make them indispensable in modern electronics, from simple dimmer power controllers to complex industrial systems.

Example of PWM Controller ICs

There are several PWM controller ICs available, each serving different purposes. The BoostWorx Pulse Width Modulation Fuel Module Controller is known for optimizing fuel efficiency in automotive applications. For renewable energy systems, the 10A 12V 24V PWM Solar Controller is essential for regulating power from solar panels to batteries. Similarly, the Universal PWM Fan Controller helps in managing fan speed intelligently, ensuring adequate cooling while minimizing noise and energy use. Another example is the 12V 2A 30W DC Motor Speed Controller, ideal for small motor applications. Each of these examples highlights the diverse uses and adaptability of PWM controllers across various fields.