This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

PCB Printed Circuit Board Assembly

Pcb Printed Circuit Board Assembly: A Comprehensive Guide

In the world of electronics, the printed circuit board (PCB) is a fundamental component that serves as the backbone for most electronic devices. The process of PCB assembly (PCBA) is crucial in transforming a bare PCB into a functional electronic device. This article delves into the intricacies of PCB assembly, covering everything from the basics to advanced techniques, ensuring that you have a thorough understanding of this essential process.

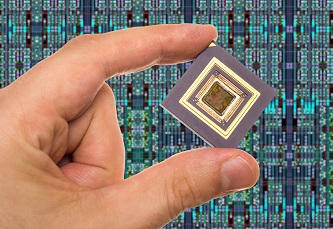

What is a Printed Circuit Board (PCB)?

A printed circuit board (PCB) is a flat board made of insulating material, typically fiberglass, with conductive pathways etched onto its surface. These pathways connect various electronic components, allowing them to communicate and function together. PCBs are used in a wide range of devices, from simple gadgets to complex machinery.

Types of PCBs

- Single-Sided PCBs: These have components mounted on one side only, making them simple and cost-effective.

- Double-Sided PCBs: These feature components on both sides, allowing for more complex designs.

- Multi-Layer PCBs: These consist of multiple layers of circuitry, enabling high-density designs for advanced applications.

- Flexible PCBs: Made from flexible materials, these PCBs can bend and twist, making them ideal for compact devices.

- Rigid-Flex PCBs: Combining rigid and flexible materials, these PCBs offer versatility in design and application.

Understanding PCB Assembly (PCBA)

PCB assembly (PCBA) is the process of soldering electronic components onto a PCB to create a functional electronic circuit. This process can be performed manually or through automated methods, depending on the complexity and volume of production.

Key Steps in PCB Assembly

- Design and Prototyping: The first step involves designing the PCB layout using specialized software. Prototyping allows for testing and validation before mass production.

- Component Sourcing: Selecting and procuring the necessary electronic components is crucial for successful assembly.

- PCB Fabrication: The bare PCB is manufactured based on the design specifications, including etching the copper traces and applying solder mask and silkscreen.

- Assembly Process: This involves placing components on the PCB and soldering them in place, which can be done through various methods.

- Testing and Quality Control: After assembly, the PCBA undergoes rigorous testing to ensure functionality and reliability.

- Final Inspection and Packaging: The final step involves inspecting the assembled boards and packaging them for shipment.

Methods of PCB Assembly

There are several methods for assembling PCBs, each with its advantages and disadvantages. The choice of method often depends on the production volume, complexity of the design, and budget.

1. Manual Assembly

Manual assembly involves technicians placing and soldering components by hand. This method is often used for low-volume production or prototyping. While it allows for greater flexibility and precision, it can be time-consuming and prone to human error.

2. Surface Mount Technology (SMT)

SMT is a widely used method where components are mounted directly onto the surface of the PCB. This technique allows for a higher density of components and is suitable for automated assembly processes. SMT is ideal for mass production due to its speed and efficiency.

3. Through-Hole Technology (THT)

In THT, components have leads that are inserted into holes on the PCB and soldered on the opposite side. This method is often used for larger components and provides strong mechanical connections. However, it is less efficient than SMT for high-density designs.

4. Mixed Technology

Mixed technology combines both SMT and THT methods, allowing for the advantages of both techniques. This approach is often used in complex assemblies where different types of components are required.

Tools and Equipment for PCB Assembly

Successful PCB assembly requires a variety of tools and equipment. Here are some essential items used in the process:

1. Soldering Iron

A soldering iron is a handheld tool used to melt solder and join electronic components to the PCB. It is essential for manual assembly and repair work.

2. Solder Paste Printer

This machine applies solder paste to the PCB in preparation for SMT assembly. Accurate application is crucial for ensuring proper solder joints.

3. Pick and Place Machine

Automated pick and place machines are used to accurately position components on the PCB before soldering. These machines significantly speed up the assembly process.

4. Reflow Oven

A reflow oven is used to heat the PCB and solder paste, causing the solder to melt and create strong connections between components and the board.

5. Wave Soldering Machine

This machine is used for THT assembly, where the PCB is passed over a wave of molten solder, allowing for quick and efficient soldering of multiple connections.

Quality Control in PCB Assembly

Quality control is a critical aspect of PCB assembly, ensuring that the final product meets the required standards and functions correctly. Here are some common quality control methods:

1. Visual Inspection

Technicians visually inspect the assembled PCBs for defects such as solder bridges, misaligned components, and other issues that could affect performance.

2. Automated Optical Inspection (AOI)

AOI systems use cameras and software to automatically inspect PCBs for defects. This method is faster and more accurate than manual inspection.

3. Functional Testing

Functional testing involves checking the assembled PCB to ensure it operates as intended. This may include testing for electrical continuity, signal integrity, and overall performance.

4. X-Ray Inspection

X-ray inspection is used to examine hidden solder joints, particularly in BGA (Ball Grid Array) components. This method helps identify issues that are not visible through standard inspection methods.

Challenges in PCB Assembly

While PCB assembly is a critical process, it comes with its own set of challenges. Understanding these challenges can help manufacturers improve their processes and outcomes.

1. Component Sourcing Issues

Finding reliable suppliers for electronic components can be challenging, especially during times of high demand or supply chain disruptions. Manufacturers must establish strong relationships with suppliers to ensure timely delivery of quality components.

2. Design Complexity

As electronic devices become more complex, PCB designs can become intricate and challenging to assemble. Manufacturers must invest in advanced design tools and skilled personnel to manage these complexities.

3. Quality Assurance

Maintaining high-quality standards is essential for PCB assembly. Manufacturers must implement rigorous quality control measures to minimize defects and ensure reliability.

4. Cost Management

Balancing quality and cost is a constant challenge in PCB assembly. Manufacturers must find ways to optimize their processes and reduce waste while maintaining high standards.

Future Trends in PCB Assembly

The PCB assembly industry is continually evolving, driven by advancements in technology and changing market demands. Here are some trends to watch:

1. Automation and Robotics

As automation technology advances, more manufacturers are adopting robotic systems for PCB assembly. This trend enhances efficiency, reduces labor costs, and minimizes human error.

2. Miniaturization

With the demand for smaller and more compact electronic devices, PCB designs are becoming increasingly miniaturized. This trend requires innovative assembly techniques and materials to accommodate smaller components.

3. Advanced Materials

The use of advanced materials, such as flexible substrates and high-frequency laminates, is on the rise. These materials enable the development of more sophisticated and high-performance electronic devices.

4. Sustainability

As environmental concerns grow, manufacturers are focusing on sustainable practices in PCB assembly. This includes using eco-friendly materials, reducing waste, and implementing energy-efficient processes.

Conclusion

PCB assembly is a vital process in the electronics industry, transforming bare PCBs into fully functional devices. Understanding the various methods, tools, and challenges involved in PCB assembly is essential for manufacturers looking to optimize their processes and deliver high-quality products. As technology continues to advance, staying informed about the latest trends and innovations will be crucial for success in this dynamic field.

Whether you are a manufacturer, engineer, or enthusiast, having a solid grasp of PCB assembly will empower you to navigate the complexities of electronic design and production effectively.