This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Understanding Automotive Certification Standards for Electronic Components

16/08/2021, hardwarebee

In this day and age vehicles must support a wide array of advanced electronic components. These components manage key vehicle functions such a safety, propulsion entertainment and communication. To ensure safe and long-term operation the automotive industry has developed important certification and qualification standards to help mitigate component operational risks.

In the following blog sections, we’ll describe the two most prominent automotive certifications, what the two standards mean, applications and what it takes to become fully certified.

Automotive Certification Standard: AEC-Q100

What is AEC-Q100?

Simply put, AEC-Q100 is a failure mechanism-based stress test qualification for integrated circuits. This automotive industry certification standard was developed by the Automotive Electronics Council (AEC) in an effort to establish common part-qualification and quality-system standards.

Does my component need to be AEC-Q100 certified?

If your answer is yes to some or all of the below questions, you have a component that needs to be AEC-Q100 certified.

- Will the component need to operate in the -40°C to 150°C temperature range?

- Will the component need to operate for ten or more years?

- Will the component acceptable failure rate need to be zero?

- Will the supply lifetime need to be fifteen or more years?

What does it take to become AEC-Q100 certified?

In order for a component to be AEC-Q100 compliant, it needs to guarantee certain levels of reliability after passing testing per the below qualification categories:

- Accelerated Environmental Stress Testing (Ex: Temperature Cycling)

- Accelerated Lifetime Simulations (Ex: High Temperature Operating Life)

- Packaging/Assembly (Ex: Wire Bond Pull)

- Die Fabrication (Ex: Electromigration)

- Electrical Verification (Ex: Electromagnetic Combability)

- Defect Screening (Ex: Part Average Testing)

- Package Integrity (Ex: Shock and Vibration Testing)

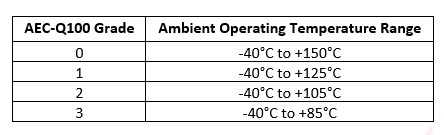

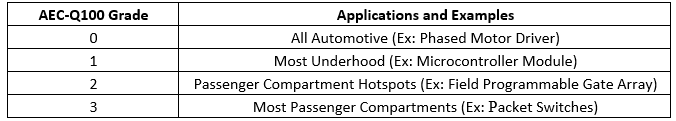

What AEC-Q100 grade does my component need to meet?

The AEC-Q100 certification contains a total of four grades. Grades for “in-vehicle” applications are highlighted below along with component and module examples:

Click here to review the detailed AEC-Q100 certification documentation from the Automotive Electronics Council (AEC).

Automotive Certification Standard: AEC-Q200

What is AEC-Q200?

The AEC-Q200 is a failure mechanism-based stress test qualification that focuses specifically on passive electronic components. This certification requires a standard for pressure resistance, temperature, and consistent safety specifications for passive components in the automotive industry.

Does my component need to be AEC-Q200 certified?

If your answer is yes to some or all of the below questions, you have a component that needs to be AEC-Q200 certified.

- Will the component need to operate in the -50 to +150 °C temperature range?

- Will the component need to operate for ten or more years?

- Will the component acceptable failure rate need to be zero?

- Will the supply lifetime need to be fifteen or more years?

What does it take to become AEC-Q200 certified?

In order for a component to be AEC-Q200 compliant, it needs to guarantee certain levels of reliability after passing testing per the below qualification categories:

- Accelerated Environmental Stress Testing (Ex: Temperature Cycling)

- Accelerated Lifetime Simulations (Ex: High Temperature Operating Life)

- Packaging/Assembly (Ex: Wire Bond Pull)

- Die Fabrication (Ex: Electromigration)

- Electrical Verification (Ex: Electromagnetic Combability)

- Defect Screening (Ex: Part Average Testing)

- Package Integrity (Ex: Shock and Vibration Testing)

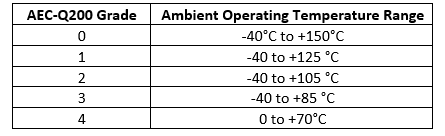

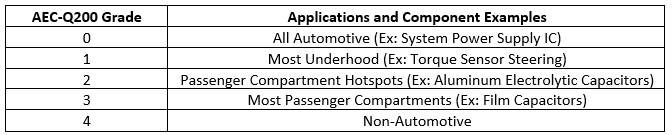

What AEC-Q200 grade does my component need to meet?

The AEC-Q200 certification contains a total of five grades. Grades for “in-vehicle” applications are highlighted below along with component and module examples:

Click here to review the detailed AEC-Q200 certification documentation from the Automotive Electronics Council (AEC).

Conclusion

To recap, the purpose of the AEC-Q100 and Q200 certification standards is to guarantee enhanced levels of module and component survivability in automotive environments. As the automotive industry evolves, implementing next generation technologies, the requirements for these certification standards will continue to grow.

When vetting potential partners for your next AEC-Q100 or Q200 qualification or test project bear in mind that the laboratory performing the work must be ISO 17025:2017 certified.

_____

This is a guest post by William Walsh, Criteria Labs. If you would like to learn more about Criteria Labs automotive qualification and test capabilities, connect with the Sales Engineering Team.

Source: aecouncil.com