The Ultimate Guide to LED Drivers

16/08/2021, hardwarebee

What are LED Drivers

A LED driver is a chip that regulates the power required for an LED or array of LEDs. The light emitting diodes are low energy, lighting devices with a long lifespan and low energy consumption, hence the requirement for specialized power supplies.

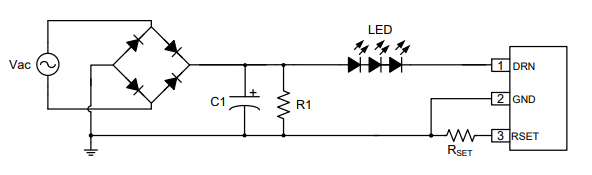

Figure 1 – A simplified LED circuit

LED drivers have two main functions: provide low voltage and offer protection for the LEDs.

Individual LEDs operate at voltages ranging from about 1.5V to 3.5V and use currents of up to a maximum of 30mA. Domestic lights may consist of several LEDs, in series and parallel configurations, and may require a total voltage of between 12 and 24V DC. The LED driver rectifies the AC and lowers the voltage to meet the requirements. This means converting the high AC mains voltage, which ranges from 120V to 230V, to the required low DC voltage.

The LED drivers also provide protection to the LEDs against current and voltage fluctuations. The circuits ensure that the voltage and current to the LEDs remain within the operating range, regardless of fluctuations in the mains supply. The protection avoids providing too much voltage and current that would degrade the LEDs or too low current that would reduce the light output.

How to Choose a LED Driver

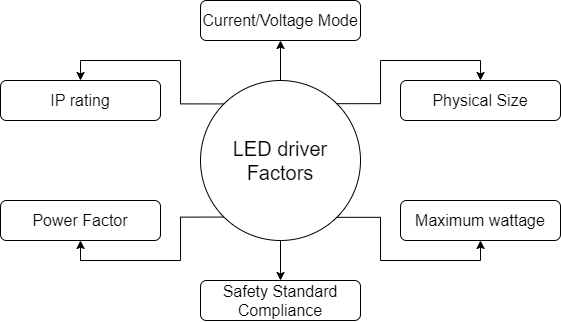

There are several factors to consider when choosing the appropriate LED driver for your application:

- Current and voltage mode: The LED drivers are either constant current, constant voltage or they can switch when needed between constant current (CC) and constant voltage (CV).

- Physical size: Physical dimensions can be a constraint for small and complicated applications, for example if the LED needs to fit into an automotive application.

- Ingress IP rating of the casing: Offers an indication of the environmental protection provided by the outer casing of the driver against ingress of moisture, dust and other objects or liquids.

- Other factors: power factor, maximum wattage, dimming ability and the compliance with international regulatory standards such as the UL1310 with regards to safety.

Figure 2 – Factors to take into consideration before choosing LED driver

Constant Current vs. Constant Voltage

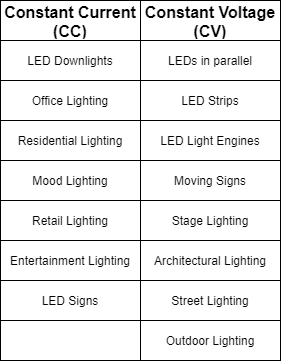

All drivers are either constant current (CC) or constant voltage (CV), or both. This is one of the first factors you need to consider in your decision-making process. This decision will be determined by the LED or module you will be powering, the information for which can be found in the LED’s datasheet.

Constant current (CC) LED drivers keep a constant electric current throughout an electronic circuit by having variable voltage. Constant current LED drivers are often the most popular choice for LED applications, as they can be used for individual bulbs or a chain of LEDs in series. A series means that the LEDs are all mounted together in line, for the current to flow through each one. The disadvantage is that, if the circuit is broken, none of your LEDs will work. However, they generally offer better control and a more efficient system than constant voltage.

Constant voltage (CV) LED drivers are power supplies. They have a set voltage that they supply to the electronic circuit. You would use Constant voltage LED drivers to run multiple LEDs in parallel, for example LED strips. Constant voltage drivers can be used with LED strips that have a current limiting resistor, which most do nowadays. The voltage output must meet the voltage requirement of the entire LED string.

Some LED drivers may feature both options of constant voltage and constant current. They normally run as constant voltage and, when the output current passes the rated current limit, they switch to the constant current mode. This functionality is suitable for applications which require a flexible LED Driver.

Figure 3 – Constant current and constant voltage LED drivers

Output Current

When using a Constant Current LED driver, check the current requirements of your chosen LED(s). The CC driver should then reflect that value output. LED’s datasheets state what they require, with the value given in amps (A) or milliamps (mA).

There are also variable and selectable output current drivers. They give either a range, for example 0 mA to 500 mA, or stepped values like 350 mA, 500 mA, 700 mA. Your LED must fall within the chosen value(s).

LEDs can be run at a lower current to help extend its life expectancy. Using a higher current could wear the LED out a lot quicker.

Output Power

This value is given in watts (W). Use a LED driver with at least the same value as your LED(s).

The driver must have a higher output power than your LEDs require for extra safety. If the output is equivalent to the LED power requirements, it is running at full power. Running at full power may cause the driver to have a shorter life span. Similarly the power requirement of the LEDs is given as an average. With tolerance added on top for multiple LEDs, you need a higher output power from the driver to cover this.

Output Voltage

This value is given in volts (V). For constant voltage drivers, it requires the same output as your LED’s voltage requirements. For multiple LEDs, each LED voltage requirement is added together for a total value.

If you are using constant current, the output voltage must exceed the LED requirements.

Life Expectancy

Drivers will come with a life expectancy in thousands of hours, known as MTBF (Mean Time Before Failure). You can compare the level you are running it at to work out the advised lifetime. Running your LED driver at the recommended outputs help to extend its life span, reducing maintenance time and costs.

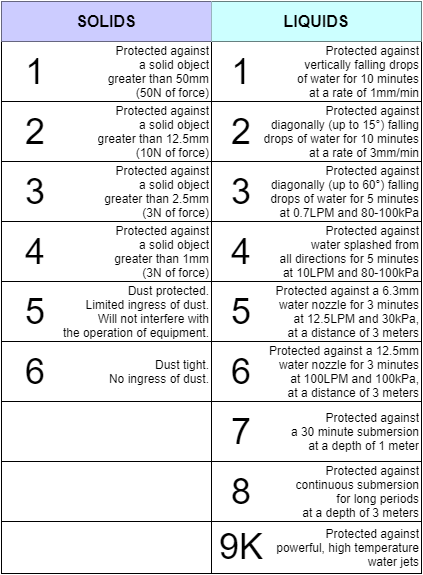

IP Rating

If your driver is going somewhere where it may come into contact with water/dust, you could use an IP65 rated driver. This means it is protected from dust and any water projected at it.

If you need something water-tight, you might need a driver with an IP67 or IP68 rating. The IP rating is given as a number. The first digit represents solid objects and the second is liquids.

Figure 4 – IP Ratings explained

Package/Encapsulation

Does your LED driver need an enclosure? Or will it be integrated into a system or device? Open frame LED drivers are more compact and can be designed into your application, while encapsulations provide IP ratings and protection for stand-alone LED drivers.

Termination Method

Some LED drivers come with flying wires attached, but sometimes you could need to purchase wires separately. Screw or poke holes also exist for quick mounting of cables to the driver.

LED Driver Categories

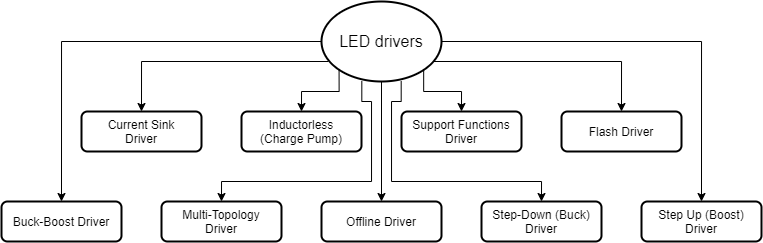

Figure 5 – Major categories of LED Drivers

Buck-Boost LED Drivers

Buck-Boost LED drivers allow LED bias when the input voltage is either above or below the LED voltage. This is ideal in cases such as a single cell lithium-ion (Li-Ion) battery driving a single LED where the input voltage can vary from 4.2 V fully charged down to 2.7 V fully depleted, while the LED forward voltage can vary from 2 V to 4 V depending on brightness and temperature.

Current Sink LED Drivers

Current sink LED drivers provide current control for multiple LEDs and protects LEDs and power supplies against thermal events, short circuits, overvoltage, and open circuit faults. These devices help enable a number of lighting technologies, including high brightness LED lighting and large format LED backlighting.

Inductorless (Charge Pump) LED Drivers

A charge pump power supply does not have inductors that are required in other Switch Mode Power Supply (SMPS) topologies. This provides a more compact and less expensive circuit.

The downside is that charge pumps cannot supply large amounts of current compared to the other topologies. Charge pump circuits are most useful for LED backlighting applications, with common applications including LCD displays and automotive instrumentation.

LED Support Function Drivers

LED support function drivers include matrix LED dimmers, PWM generators, and LED ballasts targeted for automotive, display backlighting, handheld, and general lighting applications.

Matrix LED dimmers operate in conjunction with an LED driver circuit configured as a current source, enabling individual LEDs within a string to be turned on and off. Fade transition between PWM dimming states offers more flexibility in designing matrix lighting with smoother dimming transitions. The programmable switching frequency of the matrix LED dimmer included in this LED Driver support function category helps to optimize efficiency and avoid critical frequency bands, including AM radio.

LED Flash Drivers

LED flash drivers support general LED lighting, building technology, scanning equipment, and a range of other technologies. Features such as automatic phototransistor controls, overtemperature protection, compact size, and diverse programmability options allow these devices to be used in a number of applications including:

- High brightness LED lighting

- Industrial lighting

- Camera-enabled smartphones

- Digital still cameras, camcorders, and PDAs

Multitopology LED Driver

A multi-topology LED driver is a versatile LED circuit that can support a range of step-up or step-down driver topologies. The device implements a fixed-frequency peak current mode control technique with programmable switching frequency, slope compensation, and soft-start timing.

It incorporates a high voltage rail-to-rail current sense amplifier that can directly measure LED current being used with either a high-side or a low-side series sense resistor. The amplifier is designed to achieve low input offset voltage and attain better than ±3% LED current accuracy. This is done over a junction temperature range of 25°C to 140°C and output common-mode voltage range of 0 to 60V.

The usual applications for these drivers are architectural lighting and general lighting.

Offline LED Driver

These LED circuits have an active power factor correction (PFC) specifically designed for driving LEDs from a universal input range of 90 VAC to 265 VAC. They are optimized for LED applications requiring 4 W to over 100 W of power and are also compatible with standard TRIAC in-wall dimmers.

The unique current sensing scheme delivers a well-regulated current to the secondary side without using an optocoupler, which reduces cost and improves reliability, making for a simpler and more compact footprint.

Step-Down (Buck) LED Drivers

Step-Down (Buck) LED drivers are ideal for applications where the input voltage is above the LED voltage, as in many automotive or industrial applications. These LED drivers offer the highest efficiency, lowest noise, and the smallest footprints. Some drivers even include integrated Schottky diodes, accurate LED current matching, and multiple output capability.

Step-Up (Boost) LED Drivers

Step-Up (Boost) LED drivers provide current control of multiple LEDs and support for high brightness LED lighting, large format LED backlighting, camera-enabled smart devices, and a whole range of related applications.

Figure 6 – Typical Application High Voltage LED Driver

Figure 7 – LED Driver Chip