Oven-Controlled Crystal Oscillators (OCXOs): Ultimate Guide

30/04/2024, hardwarebee

Introduction to OCXO

The oven-controlled crystal oscillators (OCXOs) are a promising technology to minimize the impact of temperature on crystal oscillators by controlling the surrounding temperature. The OCXOs produce stable frequency by controlling and regulating the temperature of the crystal element. This establishment is becoming a valuable solution for precise timing applications. This paper presents a general guideline for OCXO technology.

Definition and Overview of OCXOs

Oven controlled crystal oscillators (OCXOs) are a highly précised clock type of crystal oscillator widely used in extremely accurate and stable frequency signals. The enclosure or oven is responsible for controlling and regulating the temperature of the crystal to a certain degree. The controlled temperature around the crystal causes the oscillator’s resonance frequency to be stable. Because of this precision, OCXOs are vital for ultra-precise timing applications. The real example of OCXO is provided in Figure 1.

Figure 1 real example of OCXOs (source: RFX group corporations)

Importance of OCXOs in Precision Timing Applications

In many applications, OCXOs are very essential in solving the synchronization problems such as referencing timing, clocking, and sourcing the frequency. They provide strict timing references due to their highly stable frequency. OCXOs are vital for many mission critical applications that require device coordination. Furthermore, OCXOs are employed in measuring and testing applications to ensure the integrity and reliability of data. OCXOs serve a crucial role in radar and military applications by targeting, tracing, localizing, and navigating objects. In communication and signal processing applications, OCXOs are also employed to improve signal purity by creating minimal phase noise and stable frequency.

Principle of OCXOs

Oscillators are electronic devices that have a positive feedback gain. In the crystal oscillators, when the crystal is placed at the oscillator circuits feedback loop with an amplifier. The amplifiers start sensing and amplifying the vibration, that initiated the oscillation and continue to resonate even after the excitation ends since the output is becoming an input to the system through the feedback loop.

Basic Principle of OCXOs

In OCXOs the Quartz crystals are subjected to mechanical stress to generate electric fields, indicating that they can convert mechanical stress into electrical energy, which is the basic operation of the piezoelectric effect. The Quartz crystal has its own resonance frequency determined by the cut angle, shape, and geometry of the crystal. Since the oscillators natural frequency is sensitive to temperature, the oven of the crystal in the OCXOs is designed to address this challenge by adjusting the temperature.

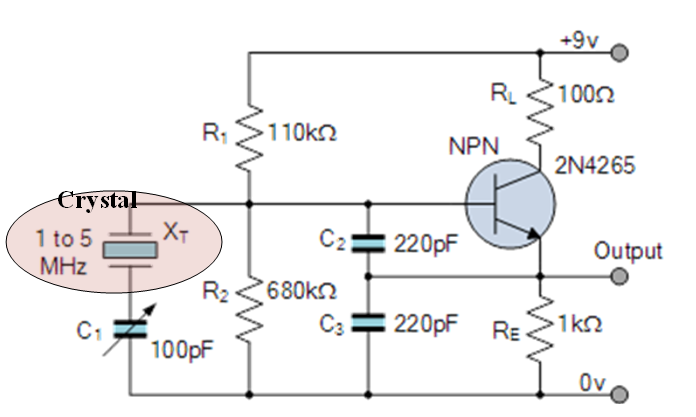

Role of Crystal in Oscillator Circuit

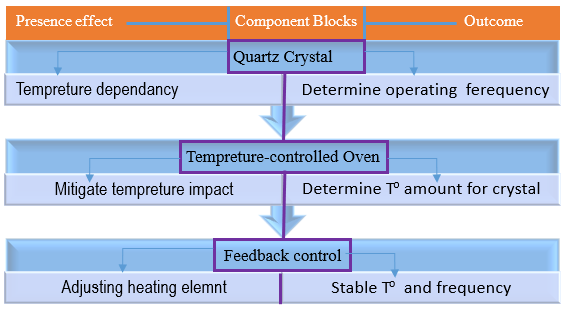

The primary function of crystal in an oscillating circuit (illustrated in Figure 2) is determining the operating frequency. It can be defined based on the size, geometry, shape, and orientation of the crystal. This can be done by the effect of piezoelectric, when an electric field is applied, the crystal will deform mechanically, this mechanical deforms; this mechanical deformation in the reverse provides an electric source that resonates at the crystal’s natural frequency. The crystal is also used as a component of the feeding loop in the oscillator circuit, which is employed to sustain the oscillation at the crystal’s resonance frequency.

Figure 2 crystal oscillator circuit details

Factors Affecting Crystal Oscillators

Temperature is one of the significant factors impacting crystal oscillators since the crystal’s resonance frequency is sensitive to temperature. Another parameter influencing the crystal oscillator is the aging of the crystal. As the age of the crystal, the physical properties are gradually changed, resulting in a drift in resonance frequency. External mechanical stress and vibrations are the other determinant factors affecting the crystal oscillators during the piezoelectricity process. Finally, fluctuations in supply power and proximity to electromagnetic objects can have a substantial impact on the oscillating circuit.

Need for Temperature Stability

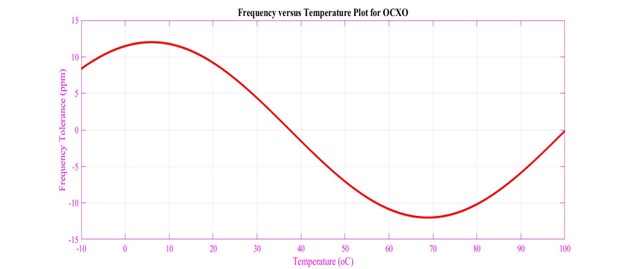

The resonance frequency of the crystal oscillator has a linear relation with ambient temperature, as shown in Figure 2. The graph illustrates that the small variation in temperature leads to a substantial shift in the resonance frequency of the crystal. The temperature stability of the crystal is expected to be below the Pico level in many applications. The need for temperature stability of crystal oscillators is to get a stable and accurate frequency for many timing applications.

In the case of OCXOs, a temperature controlled oven is integrated with the crystal to maintain the constant temperature, usually in the range of 60-80oC, to reduce the effect of ambient temperature and produce high frequency stability over temperature with a typical range of parts per million (PPM) or parts per billion (PPB). The temperature controlled oven must be highly précised and responsive to maintain the crystal temperature at the required set points.

Figure 3 Frequency tolerance versus temperature in crystal oscillators

Temperature Effect on Oscillators Frequency

Here are lists of effect of temperature on the oscillator frequency.

- The physical properties of the crystal alter with temperature

- The temperature change shifts the resonance frequency of the crystal oscillator.

- The relation between temperature fluctuations and frequency variations depending on the shapes and orientations of the crystal.

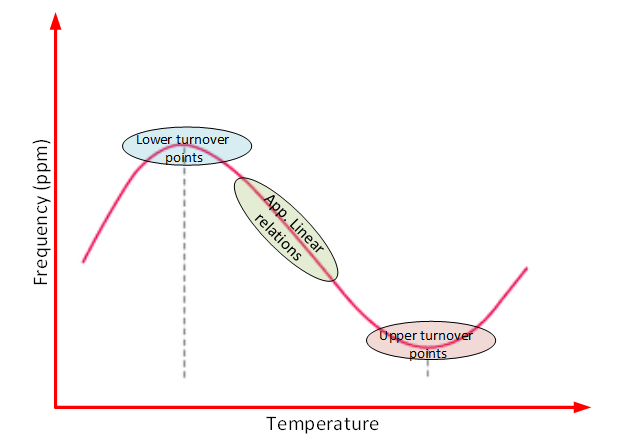

In general, temperature and frequency in crystal oscillators have a complicated relationship. To mitigate the effects on frequency stability, OCXO designer preferred to use the temperature turnover points where the frequency is less affected by temperature change, mostly in the range of 60-800C. Some factors of temperature like thermal gradients, thermal lag, and non-linearity of frequency vs temperature relation create a residual temperature effect even in the well-designed OCXOs.

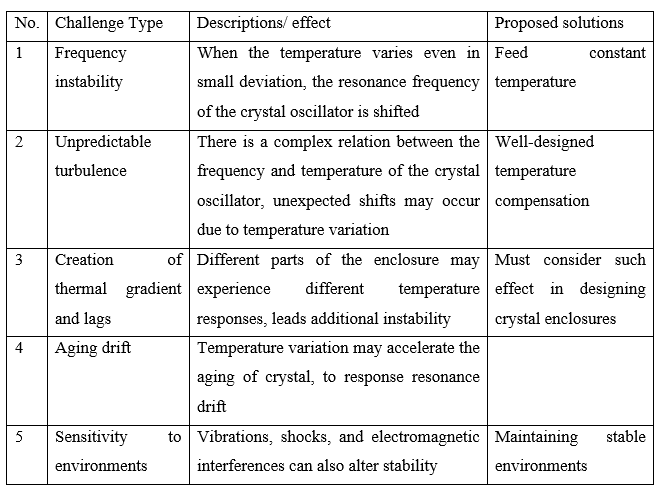

Challenges Posed by Temperature Variation in Crystal Oscillators

Temperature variation generates a great challenge in the crystal oscillators including instability of the oscillator. Table 1 summarizes challenges related to temperature variation for crystal oscillators.

Table 1 challenges of OCXO with their descriptions and proposed solutions

Importance of Temperature Stabilization in Precision Timing Application

The necessity of temperature stabilization for crystal oscillators in timing precision applications is mainly to have a stable frequency of references. This stable and accurate frequency leads to synchronous data transmission for communication services, error-free measurements, and navigation systems. Temperature stabilizing also leads the crystal to long-term stability by minimizing the temperature variation extractable physical properties for a low aging rate.

Design and Operation of OCXOs

The requirements of OCXO design are mainly on the proper component selection and careful consideration the design temperature points, which must be in the upper turnover range of the frequency versus temperature curve in the range of 60-800C, as shown in Figure 4.

Figure 4 Higher turnover points of quartz crystal

OCXO Architecture Overview

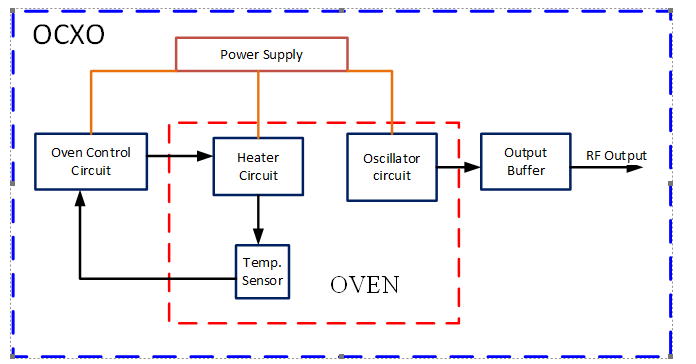

Figure 5 presents the OCXO architecture, as it demonstrates frequency is generated by the core component of OCXO, which is the quartz crystal. The architecture includes the heater circuit and temperature sensor together with a feedback circuit to regulate temperature. The oven control circuit receives sensor data and regulates the temperature based on the design at a specific degree Celsius by using a voltage regulator. The output of the oscillator is buffered and amplified for the desired purpose. In reality, OCXO uses thermal isolation to minimize the external ambient temperature effect while preserving the desired temperature set points.

Figure 5 Architecture of OCXOs

Principle of Operation: How OCXOs Achieve Temperature Stability

Figure 6 demonstrates the flow chart process to maintain the temperature in OCXO using blocks of components. The oven mainly comprises the heater, redundant temperature sensors, and thermal isolators to assert the crystal oscillator to be stable in frequency generation.

Components and Circuitry used in OCXO Design

The components and circuits used in designing OCXO are listed below:

Quartz Crystal

- Provides resonance frequency

- Shape, size, cut angles, To, affect its frequency

Oscillator Circuit

- Feedback oscillator

- Generates electrical signal that drives the crystal to oscillate

Temperature Controlled Oven

- Enclosure that surrounds quartz crystal

- Provides a constant and stable To for Crystal

- Typical value 60-800C

Heating Element

- A resistive heater

- Quickly adjust the temperature of oven environment

Temperature Sensor

- Thermistor or resistance To detector (RTD)

- Continuously monitor the To of the crystal and oven

- Temperature control system

Temperature Control System

- Integrate with microcontroller

- Receive data from sensor and regulate precisely at desired To

Thermal Insulations

- Minimizes heat transfer between the environment and the oven

- Helping to maintain To in the oven

Voltage and Power Regulation

- Stable and regulated power supply for

- OCXO components like control circuit, oscillator circuit

Frequency Output

- A stable oscillation signal from the quartz crystal is conditioned and buffered

- The output can be used for precision timing references

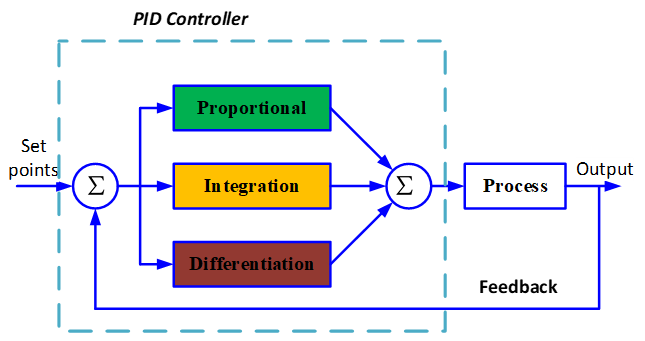

Thermal Control Mechanisms

Thermal regulation in OCXO is achieved by rigorous design and material selection procedure. For instance, the ovens are fabricated from materials that conduct heat efficiently like aluminum, and withstand heat gradients. The thermoelectric heater rapidly responds to the control signal to stabilize temperature by proportional-integrated-derivative (PID) algorithms. The algorithm monitors the temperature signal and drives the heater as per demand through a pulse width modulated (PWM) signal. The feedback loop continuously re-entered the temperature value of the oven room at the set points and the thermal isolation isolates the oven from the environment. In this process, thermal control mechanisms can be maintained at constant temperature.

Ovenized Enclosures in OCXO

The ovenized casing differentiates the OCXOs from other types of oscillators. Ovenization aims to create a stable and controlled temperature in the oven room, where the crystal element is inside. Ovenized enclosure requires the temperature sensitivity of the crystal, a precise temperature sensor, a responsive heating element, a sophisticated feedback control system, a temperature control mechanism, and superb thermal insulation. The combination of an insulating oven and closed loop temperature controlled techniques can produce a stable temperature for the crystal and highly reduce the impact of ambient temperature.

Functionality of thermal insulation and heating elements

The function of thermal insulation in OCXO is to resist heat transfer between the surrounding environment and the ovenized enclosure in the OCXO architecture. That reduces the impact of ambient temperature variation on the enclosure crystal, which leads to temperature stability. The purpose of the heating element is to adjust the temperature of oven environment to maintain the temperature, which is mostly a resistive heater. These elements are coordinated with the temperature controlled system to create better stability in temperature.

Temperature controlled algorithms and feedback system

The real-time temperature condition of the crystal oscillator in OCXO is detected by a temperature sensor and sent via the feedback circuit to the temperature controlled algorithm. The algorithm in the microcontroller processes the sensor data and precisely regulates the temperature of the OCXO crystal. Among the top-rated temperature controlled algorithms, PID (proportional-integrated-derivative) is commonly employed in OCXO via a closed loop feedback system. As demonstrated in Figure 7, the PID takes the difference between the specified value and sensed data for heating element adjustments.

Figure 7 Block diagram for PID controller

Performance Characteristics

The performance characteristics of OCXOs are measured by how fit they are at the highest level of timing precision and frequency stability. Let this article address the key performance parameters and their corresponding possible value interpretations in the OCXO.

Key Performance Parameters of OCXOs

- Temperature sensitivity: It measures the temperature-induced frequency variation of the crystal; the better crystal is less sensitive to temperature variation.

- Power consumption: especially portable systems the power consumption of OCXO is also one parameter, the system must be design to use optimized power

- Frequency stability: The main performance metric of the oscillator is frequency stability, measures the stability level of oscillating frequency in terms of parts per million of parts (ppm) per billion (ppb). The well-designed OCXOs are more stable and highly required for time precision applications.

- Aging Rate, reliability, and lifetime of the crystal are also other important performance parameters of OCXO.

Frequency stability over temperature and time

A major challenge in crystal oscillators is their temperature dependency and OCXO addresses this challenge by temperature controlled oven techniques and thermal insulation methods to minimize temperature fluctuation over the crystal. In the well-designed OCXO, the temperature coefficient is low enough as parts per million per degree Celsius (PPM/oC) or Parts per billion per degree Celsius (PPB/oC). In addition, to frequency stability over temperature, there is also another parameter over time, which is said to be the aging of the crystal. The physical properties of the crystal are change over time resulting in frequency drift. The aging rate of highly qualified OCXO must engineered at less than 1 parts per million (PPM) per year.

Phase Noise and Jitter Specifications

The short-term frequency stability of oscillators can be examined by the phase noise, which measures the random fluctuation of the output signal in the phase. The OCXOs are designed to have a low level of phase noise, decibels relative to the carrier (dBc/Hz) at offset frequencies from the carriers, which is very essential in telecommunication and signal processing applications. A parameter that measures a short-term variation in the timing of the oscillator’s output is called a jitter. It is related to OCXO phase noise performance in time domain uncertainties. Jitter in OCXO designs is expressed in terms of root mean square (RMS) over a frequency range.

Applications of OCXOs

No one undermines the criticality of OCXO applications in many of our day-to-day activities. Several technologies in the current telecommunication sector, satellite, and aerospace, industries, embedded systems, and automotive industries are requiring stable clocks. Pulse generation and signal analysis in scientific measurements are also the product of stable frequency OCXO. This article will disclose some of the applications of OCXO as follows:

Industries and applications requiring high precision timing

- Telecommunication: OCXOs are required to produce precise synchronization and timing between cellular networks, satellite communications, and internet backhauls with stable frequency, low jitter, and minimal phase noise.

- Military technologies: Highly accurate timing reference from OCXO is required for radar systems and navigation in military technologies.

- Instrumentations: Advanced research facilities including particle accelerator and telescopes are based on the accurate timing of OCXO.

- Smart grid applications: The efficient energy distribution and monitoring require precise timing references between grid components which is done by OCXO.

- Financial transaction process: Accurate time stamping and synchronization are critically used by stable frequency generators in any trading platform and transaction process.

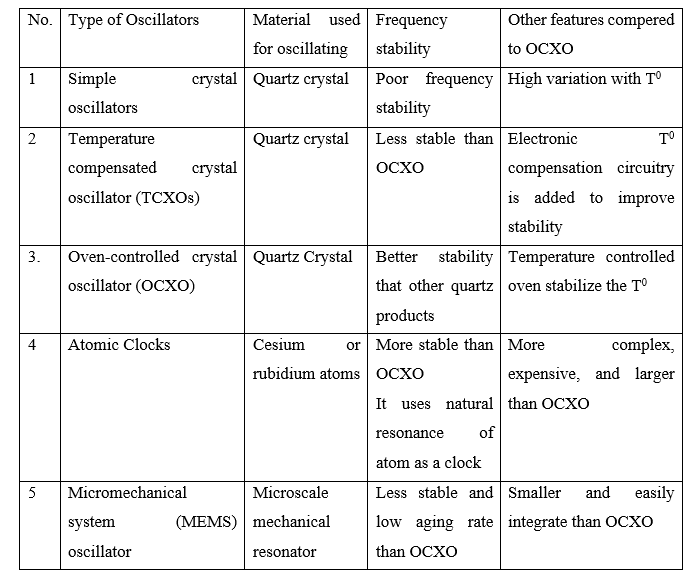

Comparison with other types of Crystal oscillators

Table 2 summarizes the comparison between OCXO and crystal oscillators

Advantages and Limitations

Advantages of OCXOs over other oscillator types

- It can generate stable frequency and temperature-insensitive

- The temperature-controlled oven also helps to reduce the aging rate

- Low phase noise and jitter RMS

- Due to thermal insulation, it is environmentally resilience

Limitations OCXOs

- The temperature regulating system including controlling circuitry, and heating elements, consumes relatively high power and increases complexity.

- The ovenized enclosure and supporting circuitry increase the size and weight of OCXOs

- It is a little more expensive than simpler oscillators due to advanced design, components, and fabrication process

- OCXOs require a few minutes as a warm-up time to reach the required set point, also considered as a limitation.

Trade-offs between performance, size and power consumptions

Most of the advantages and good performances of OCXO are from temperature controlled components, however, they increase size, power consumption, and complexity as presented in the limitations. The designers must consider and create a balance between the trade-off between good performances versus size and power consumption in the OCXOs based on the available space, performance desires, and energy constraint application requirements.

Future trends and Developments

Most of the emerging trends of OCXOs are highly focused on minimizing their limitations and improving their performances. The emerging microcontroller and packaging technologies are aligned with the miniaturizations and high level of integration improvements in OCXOs. So in the future OCXOs demanded to be smaller in size, more compact, and easily integrated to any space-limited devices. The innovative technologies towards thermal insulation and heat dissipation techniques are highly essential in introducing and further improving the closed loop temperature control system, which assists OCXOs for better frequency stability and lower aging rate. The energy optimization techniques and adaptive power control algorithms make OCXOs more power efficient without impacting temperature stability in the future. Continual exploration of new crystal material, and advancement in crystal cut and coating to reduce the aging rate and temperature sensitivities are also other new developments in the OCXOs. Integrating OCXOs with digital frequency synthesizers to create software-defined multi-frequency services and others are some potential solutions for future OCXOs. These emerging trends allow OCXOs to remain at the forefront of the précising timing and stable frequency mission-critical applications.

List of OCXO Vendors

Dynamic Engineers: www.dynamicengineers.com

Euroquartz: www.euroquartz.co.uk

Golledge: www.golledge.com

Bliley Technologies: https://www.bliley.com/