Temperature-Compensated Crystal Oscillators (TCXOs): Ultimate Guide

29/04/2024, hardwarebee

Introduction

Temperature-compensated crystal oscillators (TCXOs) are enhanced crystal-type oscillators that integrate temperature compensation techniques to minimize frequency instability by temperature variations. It is a good choice for precise and stable clock signals than traditional standard oscillators. TCXOs are preferred since temperature variations can be addressed by adding temperature-compensated circuits, which helps the crystal to have a consistence temperature even when fluctuations appear in the surroundings. This article is composed of a general review of TCXO’s importance, principle of operation, temperature compensation mechanisms, design and required components, the future trends and developments.

Definition and Overview of TCXOs

TCXO is a short-hand representation of the Temperature Compensated Crystal Oscillator an electronic device that generates clock signals in multiple applications with better frequency stability with temperature variations. TCXOs integrate into devices where precise timing and synchronization are required. TCXO uses a quartz crystal as a primary component for oscillation. However, this component is highly temperature-dependent by nature. Thus, temperature compensation provides a constant temperature irrespective of the ambient temperature variations, which makes the general electronic oscillating system stable with any temperature fluctuations.

Importance of TCXOs

TCXOs employ temperature compensation techniques in producing stable and precise frequency signals. Once the frequency stability is settled, TCXOs are integrated into many applications to provide precise timing and synchronization. In addition, TCXOs may be used to enhance signal quality by minimizing random fluctuations due to their low-phase noise and high-level data integrity. TCXOs have a short warming-up time to stabilize the system temperature and resume normal operation within a few seconds after turning on the power.

Operational Principle of TCXOs

The operational principle of TCXOs towards its temperature stabilizing objective in the crystal system connects many components. The quartz crystal is responsible for frequency generation with the help of the oscillator circuit that forces for piezoelectric effect. The oscillator circuit provides an applied electric field to the quartz crystal that is subjected to mechanical stress and vibration at a precise and stable frequency. The resonance frequency or natural frequency of a crystal is determined by the physical dimensions and properties of the crystal, however, this resonance frequency is highly unstable with temperature variations.

Temperature compensation operation includes a temperature sensor to monitor the level of the system temperature in the vicinity of the crystal and gives feedback to the compensation circuit. The compensation circuitry system is responsible for adjusting the frequency drift towards a specified level as per the feedback information. This type of circuit usually consists of temperature dependent components for fast stabilizing the frequency drift by modifying the supplied controlled voltage or current to the crystal oscillator circuit. Due to the feedback circuit, the compensator compares the actual frequency output from the oscillator and the desired stable frequency and then makes a necessary adjustment to the control parameters. The compensation circuitry can effectively counteract the frequency variations caused by temperature changes.

Factor Affecting Stability and Accuracy of TCXOs

In temperature-compensated crystal oscillators (TCXOs) the stability and accuracy of operation are largely affected by temperature change. Even if TCXO employs temperature compensation techniques for determining the effectiveness of stable operation, still temperature fluctuation affects the frequency stability. Besides the direct temperature variation, thermal and temperature gradients in TCXOs affect the stable operation by creating irregular heating or cooling of the crystal resonators resulting in non-uniform frequency offsets.

The internal properties of crystals are also affected by the over-time operation, that drifts the natural frequency, this is called crystal aging. For long-time stability many innovative techniques are applied to reduce the aging rate of the crystal, nevertheless, aging is a gradual process caused from by mechanical stresses and environmental impacts. Moreover, TCXO’s stability is affected by the coupled electrical noises from the surroundings and electromagnetics interferences, which introduce unwanted frequency variations. The discrepancy in the applied power, the impedance of the connected output devices, and external mechanical stress are also affecting the stability and accuracy of TCXOs.

Temperature Stability of TCXOs

Temperature stability in TCXOs is vital to maintain the constant frequency output irrespective of temperature variation. The temperature stability is considered as one parameter of TCXO and expressed as parts per million per degree Celsius (ppm/0C). The temperature stability significantly depends on the quality of the compensation circuit, the physical properties of crystal oscillators, the accuracy of the temperature sensor, design considerations, and manufacturing precision. Thus, TCXOs may be designed in different specified temperature stability with different temperature ranges, the users must identify which range of temperature by what stability is better for their applications. High-quality TCXO provides better temperature stability with controllable and stable frequency tolerances over a wider range of temperatures.

Effect of Temperature on Frequency

In all crystal oscillators temperature has a direct impact on the frequency stability as they have linear dependency. To describe the effect of temperature in TCXOs operation, it is better to pick the effect of temperature parameters in the crystal such as temperature coefficient, frequency division, and drifts. The temperature coefficient (Tc) is the representation of change in frequency ( ) per temperature variations ( ), as shown in the equation below.

The value of the temperature coefficient can be positive or negative based on the properties of the crystal and oscillator design like crystal cut and compensation techniques. The negative coefficient shows that the temperature increases while the frequency decreases, and the positive coefficient means both frequency and temperature can increase or decrease in a similar direction.

Temperature Variation Challenge

The challenge of temperature variation in TCXO is producing frequency instability. The instability is due to the natural frequency of the crystal being significantly sensitive to temperature change. In addition, temperature gradients with different parts of TCXOs introduce other temperature variations in the oscillator which leads to frequency drift. In TCXO the complex nature of the compensation circuit to mitigate temperature requires careful consideration for properly managing the temperature. In addition, temperature variation may be caused by environmental factors and long-term aging of the crystal, which all result in frequency instability. To address these temperature variation challenges, it is required to have proper material selection and high-level designing, packaging, and precise thermal management strategies in the compensation circuitry are needed.

Importance of Temperature Stability

The advantages of TCXOs are highly correlated to the importance of temperature stability. These include timing accuracy, stable frequency generation, high-quality data integralities, system performance, and compatibilities are some of the advantages of temperature stability in TCXOs. Any application that requires precise timing for data and machine synchronization employs TCXO in the range of stable temperatures. A stable and high-quality signal can be produced by the oscillator when the temperature is stable. If the temperature is not stable the data is corrupted, and synchronization issues are not targeted, it will degrade system performances. Overall, to use TCXO as a source of signaling, temperature stability must be highly maintained to obtain accurate timing, reliable frequency, and optimal system performance.

Design and Operations of TCXOs

In the design of TCXOs, several key elements must be considered starting from crystal element selection to packaging TCXOs. However, there is no specific design for TCXOs as it varies among models and manufacturers. The user has to deeply refer to the application notes, manufacturer’s datasheet, and specifications for detailed information about specific designs. This article slightly presents the general design procedure for TCXOs.

Design Considerations

When designers design TCXOs, they have to carefully track the following procedures and recommendations. In material selection, the quartz crystal must have a low aging rate and be less sensitive to environmental factors. In addition, dimensions, crystal cut, and orientation are critical for the achievement of the desired natural frequency.

The designer also significantly considers TCXO’s temperature compensation circuitry, which is a combination of many circuit elements and control parameters. So choosing appropriate circuit elements, putting in the proper placement in the circuit, and setting up a good adjustment for temperature variations are critically considered. Furthermore, TCXOs require efficient design in controlling techniques that adjust the frequency via the sensor signal from the feedback circuit. Effective thermal management system, extensive carefulness during manufacturing and packaging, and considering the rest mechanical and environmental factors are additional design considerations for high-quality TCXOs.

TCXOs Architecture and Functionality

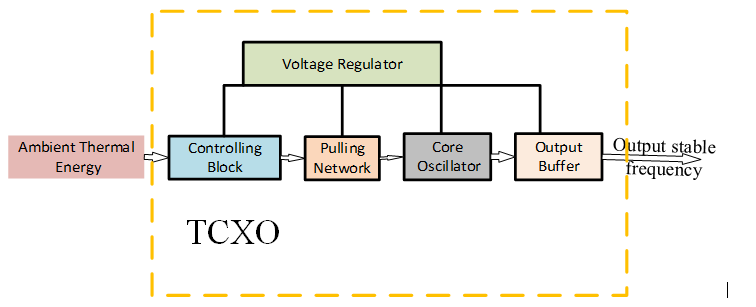

TCXOs operate in a specific range of temperatures with frequency stability. TCXO functionality can be detailed by blocks of its architecture shown in Figure 1.

Figure 1 Basic TCXO Architecture

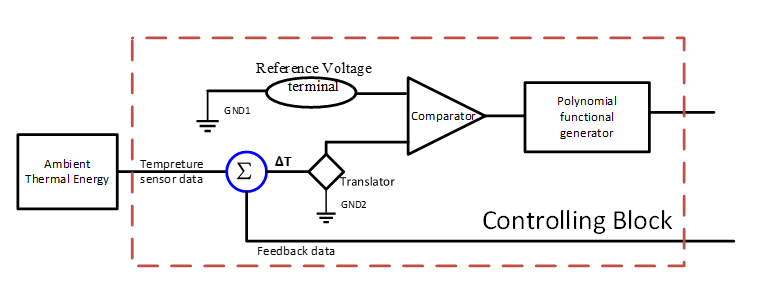

Controlling block: It is the key component of TCXOs by generating the controlling signal, it senses the change in ambient temperature from the environment with the help of a sensor and feedback circuit. It uses a comparator with a predefined reference voltage to translate the sensed temperature change to a proportional voltage. Then, the temperature voltage is translated into a specified controlling voltage using a polynomial functional generator. Nevertheless, all crystal has their temperature characteristics, to determine the coefficient of the polynomial function for every crystal a step-by-step compensation process is required. As a result, TCXOs are becoming a precise and more expensive than other standard oscillators.

Figure 2 Controlling block of TCXO by polynomial functional generator

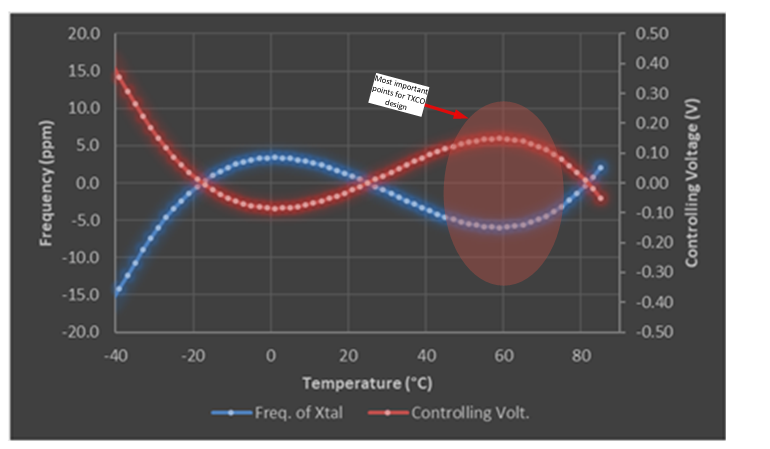

Figure 3 Frequency and controlling voltage versus temperature characteristics

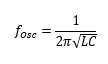

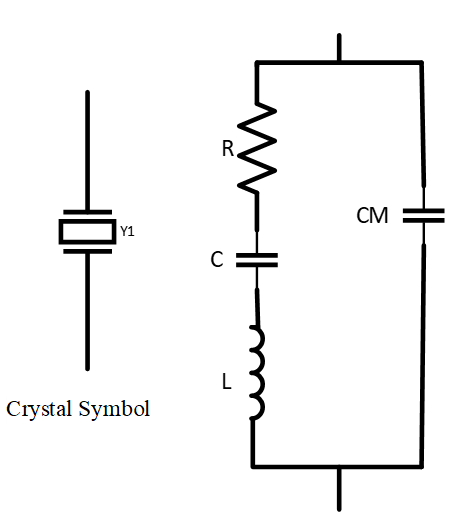

Pulling Network: This circuit is responsible for correlating the frequency variation of oscillators due to temperature fluctuation with the controlling voltages. The inductance (L) of a quartz crystal varies with temperature. Thus, the oscillator frequency is easily compensated by adjusting the capacitor as indicated by the following equations. Figure 4 illustrates the equivalent circuit of crystal.

Figure 4 Equivalent circuit of Crystal

The array of varactor are responsible for capacitor adjustment with the help of controlled applied voltage. The varactor uses the controlling voltage to adjust the equivalent capacitance to a direct response for resonance frequency stabilization in temperature variation.

Oscillator Circuit: TCXOs have an oscillator circuit that is designed to optimize and generate a desired frequency from the crystal by creating a piezoelectric effect.

Voltage regulator: It is used to regulate the voltage of TCXOs from outside to prevent any voltage fluctuation within TCXOs by noise of the supply.

Output Buffer: It is an isolation system for crystal oscillators from any external load change and leads output load capacitance to impact less on the stable frequency generation.

Components and Circuitry of TCXOs Design

The detailed components and circuits of TCXOs are summarized and mentioned below, with their corresponding functionalist in each block.

Temperature sensor – To monitor the surrounding temperature and feedback to the compensator circuit

Compensator circuit – Adjusting the frequency of output after receiving the TCXOs feedback. It consists of resistors, capacitors, varactors, and digital logic circuits

Quartz Crystal – Producing the resonance frequency

Varactors – Adjusting the resonance frequency with temperature variation

Oscillators Circuit – Generates the oscillating signal using a crystal resonator

Power Supply Circuit – Generate a stable power for TCXO components

Interfaces Units – Controls the logic and interface for external adjustment for frequency programming or calibration

Temperature Compensation Mechanisms

The temperature compensation mechanisms in TCXOs aim to regulate the temperature of the crystal resonators and other temperature sensitive components. The compensation maintains temperature stability and reduces the thermal effect on the resonance frequency. For the temperature compensation processes, several techniques are employed in TCXO.

- Thermistor Compensation: TCXOs may include a temperature sensitive resistor which is a thermistor to measure the environmental temperature change. The result is used to adjust the compensation circuitry to compensate for the frequency drift.

- Voltage-controlled TCXOs (VC-TCXOs): The TCXOs compensation technique used a controlled voltage to adjust the bias voltage supplied to the crystal.

- Current Controlled TCXOs (CC-TCXOs): The compensation circuitry is controlled by the current rather than the voltages to adjust the frequency variation due to temperature change

- Temperature-dependent compensation: The compensator may use temperature dependent resistors, capacitors, and varactors to depict temperature change and counter-response for frequency variations

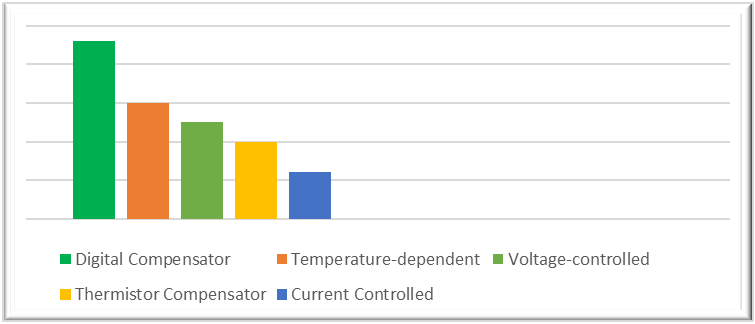

- Digital compensations: Advanced TCXOs employ microcontrollers and digital signal processors to monitor and apply compensation algorithms to adjust the controlling parameter for improving stability.

In general, the compensation process utilizes temperature sensor feedback, thermal insulations, effective heat dissipation methods, and optimization and calibration of thermal time constants of TCXOs to improve frequency stability and minimize the impact of temperature change on TCXOs output. While packaging the TCXOs, it is also critical to consider enclosure equipment’s thermal properties, the reaction to environmental conditions, and mechanical factors to increase the reliability and durability of TCXOs. Figure 5 compares the temperature compensators in terms of the frequency of utilization in the industries.

Figure 5 Comparisons between frequently employed compensation techniques in the market.

Performance Characteristics

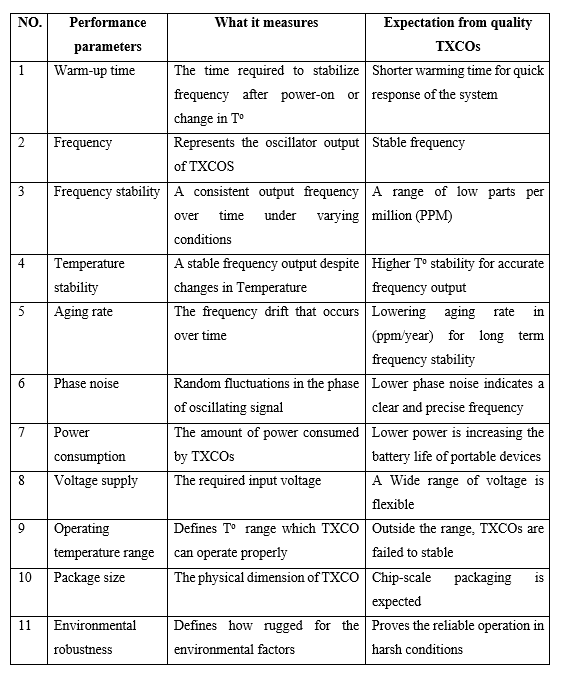

Table 2 Performance parameters and characteristics of TCXO

Even though TCXO’s designs and performances vary with the required applications, there are some key performance parameters that measure how well-suited for a general application. The quality of TCXOs can be easily traced these performance metrics. Table 2 summarizes the key performance parameters, what they measure, and what is expected from a well-designed TCXO oscillator.

Applications of TCXOs

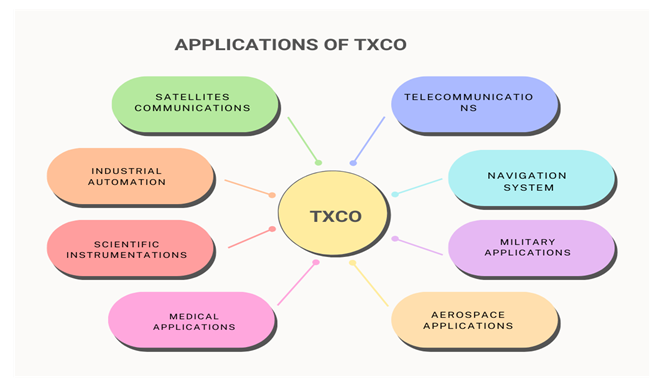

TCXOs have been employed in many electronics systems and industrial sectors as referencing accurate and stable frequency. Just a few examples from abroad range of applications like in telecommunications and wireless linking systems used for network synchronizations. In global navigation satellites, TCXOs are utilized for precise positioning, navigation, and timing functions. In military and aerospace applications utilized for targeting, implementing onboard instrumentations, and guiding flight objects. Furthermore, TCXOs are integrated into industrial automation for synchronizing the distributed control system, PLCs, robotics, and precision instrumentations. More importantly, TCXOs are used in scientific instrumentations for testing and measurement equipment to generate a stable signal, such as frequency counters, oscilloscopes, medical imaging, spectroscopy instruments, and others.

Figure 6 Application summary of TCXO

Comparison with other Oscillators

When comparing TCXOs with other types of oscillators, it is vital to examine their respective features in terms of the benefits and limitations of TCXOs. Relative to standard crystal oscillators, TCXOs are more temperature stable. Voltage-controlled crystal oscillators (VCXOs) are more common in modulation and they are designed where the input voltage controls the frequency tuning. TCXOs have better frequency stability over a wider range of temperatures than VCXOs. When TCXOs are compared to OCXOs (controlling crystal temperature to stable temperature), OCXOs provide better stability in frequency. However, OCXOs are large, consume more power, and requires much warm-up time in contrast to TCXOs. Rubidium oscillators are highly accurate and stable in frequency than TCXOs, but more power hungry, complex to use, and expensive than TCXOs.

Limitations of TCXOs

Even though several improvements have been made to enhance the performance of TCXOs further from standard oscillators, still several under-listed limitations should be considered when designing or utilizing TCXOs.

- TCXOs are operated in a limited temperature range, they are not stable out of the range

- They required further improvements in temperature stability, power consumption, and phase noise relative to more advanced oscillators.

- The aging effect and long-term frequency stability are still a limitation for TCXOs

Future Trends and Developments of TCXOs

Current Advancements

Currently, some advancements are undergoing to improve the performance of TCXOs which includes enhancing temperature compensation circuits and algorithms to increase the frequency stability. The size miniaturization, integrating capability with other components, and lowering power consumptions are the additional current advancements in TCXO technology.

Emerging Trends

The emerging trends related to TCXOs are proposed to offer better temperature stability and flexibility over the traditional TCXOs. The Hybrid TCXOs combine digital and analog compensation techniques, the MEMS-based TCXOs for smaller and more robust, and software-defined TCXOs for greater flexibility and customization are the coming technologies on TCXOs.

Potential Innovations and Improvements

Some of the challenges related to TCXO may be solved by AI algorithms like real-time monitoring and frequency calibrations, that significantly assist the compensated circuits to easily increase the stability. The material advancement technologies on the other side will improve the TCXO’s component qualities for enhanced frequency stability.

Examples of TCXO Suppliers