FPGA Prototyping

22/02/2021, hardwarebee

What is FPGA Prototyping?

FPGA prototyping is also known as ASIC based prototyping or System-on-Chip prototyping. It is the process of prototyping SoC and ASIC designs on FPGA chips before the final implementation (e.g. tapeout). This practice is becoming more and more common as it helps verify the hardware design early in the process, making the process more error-free and cost effective.

Ever wondered how tech companies rapidly develop sophisticated hardware solutions? FPGA prototyping is a pivotal technology in the fields of hardware design and system development, known for its unmatched flexibility and speed. This approach allows designers to test and refine ideas on actual hardware, significantly reducing time-to-market compared to traditional methods.

FPGA, or Field Programmable Gate Arrays, are integrated circuits designed to be configured by the customer after manufacturing. This guide will explore the depths of FPGA prototyping, highlighting its significance and advantages over conventional emulation techniques, such as cost-effectiveness, infrastructure flexibility, and portability. Despite its benefits, this methodology also presents challenges like technical hurdles and debugging visibility issues that developers often face.

Read on to discover the comprehensive steps of the FPGA prototyping process, the range of tools and techniques available, and the cutting-edge applications in industries like 5G networks and high-performance computing.

Understanding FPGA Prototyping

FPGA prototyping is a vital aspect of digital circuit design and software development. It involves using Field-Programmable Gate Arrays (FPGAs) to test hardware designs before they are finalized. This process provides a flexible and efficient way for design teams to evaluate and refine their ideas. As technology advances and systems on chips (SoC) become more complex, prototyping platforms like FPGA play a key role in shortening development timelines. They help bring original designs from concept to reality, seamlessly bridging the gap between hardware design and software operation.

Definition and Importance

FPGA prototyping involves using FPGAs to create an initial version of a hardware design. This initial model helps developers identify errors and refine concepts. It’s an essential step in the design process because it enables teams to test ideas in a real-world setting before committing to mass production. This approach is for SoC design, where intricate software development and interaction with hardware accelerators come into play. A prototyping board allows for immediate adjustments, making it easier for software and hardware teams to collaborate. In this way, FPGA-based prototyping serves as a cornerstone for efficient and accurate digital circuit development.

Key Benefits

FPGA prototyping offers several key benefits that are hard to overlook. Firstly, it enhances the speed of the development process. By using FPGAs, design teams can quickly iterate and improve their designs without the expense of manufacturing custom chips initially. This makes the whole design process more agile and responsive to changes.

Furthermore, FPGA prototypes provide a reliable platform for software simulations. They help in assessing how software stacks perform on actual hardware. This serves to smooth the overall software development process and ensures that the final product operates as expected. Additionally, FPGA prototyping aids in adhering to strict design guidelines, which is vital for maintaining quality and compliance in hardware design projects.

Lastly, it supports the education of budding engineers in digital design courses. By engaging with FPGA prototyping, students can grasp the concepts of software and hardware design in a practical setting. This hands-on experience is invaluable, equipping future engineers with the skills they need for innovating in the fast-evolving tech landscape.

Comparing FPGA Prototyping with Traditional Emulation

FPGA prototyping and traditional emulation are both valuable methods in the design process. Each has its own strengths and fits different needs in hardware design. FPGA prototyping is often used for validating digital circuits and enhancing system-on-chip (SoC) designs. It lets design teams test their ideas early in the development process. On the other hand, traditional emulation focuses more on the complete system performance, testing software operation alongside hardware. This comparison will explore aspects such as cost-effectiveness, infrastructure flexibility, and portability advantages.

Cost-Effectiveness

When it comes to cost, FPGA prototyping holds a significant advantage. The initial investment in prototyping boards can be lower compared to traditional emulation systems. Once purchased, these boards serve multiple uses throughout the design process. They offer a cost-effective way for design teams to experiment and conduct digital design courses. The savings continue as teams use open-source software tools and source software projects, further reducing expenses. By cutting costs in both hardware and software development, FPGA prototyping becomes an efficient choice for many developers.

Infrastructure Flexibility

Infrastructure flexibility is essential in the rapidly changing world of hardware design. FPGA prototyping provides a versatile platform for both hardware and software development. Teams can dynamically adjust their approach as the project evolves. This flexibility allows for quick iterations and easy modifications, useful when following strict design guidelines. Developers can integrate software stacks and use software simulations to test changes rapidly. Unlike traditional emulation, where changes can be more cumbersome and time-consuming, FPGA prototyping allows for seamless adaptations in the prototyping environment.

Portability Advantages

Portability is another area where FPGA prototyping excels. With FPGA-based prototyping, developers benefit from a system that is both lightweight and easy to transport. This portability means that design teams can work across different locations without worrying about complex setups. It allows for collaboration in various prototyping systems, enhancing teamwork across different departments. As a result, teams can bring their hardware design and virtual prototyping experience to different settings effortlessly. This portability also aids in hybrid prototyping, combining the benefits of FPGA with traditional methods. By providing a portable and adaptable solution, FPGA prototyping supports a smooth and efficient development process.

Common Challenges in FPGA Prototyping

FPGA prototyping is an important part of the hardware design process. It allows design teams to test and refine their systems on a prototyping platform before finalizing the product. However, the process isn’t without challenges. These hurdles can affect the efficiency of both software and hardware development. Design teams often face technical hurdles that complicate their work. Manual interventions, debug visibility issues, and long compilation times are among the common challenges that teams encounter. Addressing these issues requires understanding the complexities underlying FPGA-based prototyping. This prototyping process is essential for developing reliable digital circuits and hardware accelerators. As a result, the obstacles also highlight places where improvements can enhance the overall development process.

Technical Hurdles

In the FPGA prototyping environment, technical hurdles often arise. These challenges can impact the effectiveness of prototyping systems and tools. When dealing with SoC design and software stacks, teams may find it hard to integrate different software tools and hardware. The design process involves a complex mix of digital design courses and strict design guidelines, making adaptability a key challenge. Additionally, original design elements must align with newly created concepts of software. Balancing these aspects is no easy task. Without careful handling, design teams can face issues in the synthesis tool and virtual prototyping stages. Solving these problems means improving both software operation and hardware design.

Manual Interventions

Manual interventions in FPGA prototyping are frequent yet cumbersome. Often, design teams must step in to adjust the software development platform and controllers manually. This interrupts the design flow and slows down the prototyping process. As hardware designs evolve, ensuring software simulations and operations match the latest version is crucial. This task often requires frequent updates of software development tools. Over-reliance on manual processes can lead to human errors that affect the quality of the final product. Design teams aim to reduce these interventions by adopting automated systems. This allows for seamless updates and reduces risks during prototyping.

Debug Visibility Issues

Debugging plays a vital role in FPGA prototyping, but visibility issues can complicate the process. When working on prototyping boards, it’s often hard to identify bugs or errors within digital circuits. Lack of visibility impacts the software development tool suite needed for efficient debugging. The software team must depend on software simulations to test and refine their designs. However, these simulations can’t always provide clear insight into hardware accelerators. If debug visibility remains poor, it can extend the development process. Enhancing debug capabilities helps design teams catch errors early and fix them swiftly. Improved visibility also provides clearer insights during synthesis tool assessments.

Compilation Time Concerns

Prototyping boards often struggle with long compilation times, which is another challenge in FPGA-based prototyping. Long compilation times can hinder the software team as they wait for results before moving ahead in the digital circuits and hardware design phases. These delays slow the development process and impact productivity. Factors like optimization techniques in software tools can sometimes help, but they aren’t always enough. Shortening compilation times requires striking a balance between efficient software operations and meticulous attention to detail. Design teams must explore new technologies and techniques to overcome this hurdle in the hybrid prototyping environment. Doing so can result in faster, more efficient hardware and software development cycles.

Tools and Techniques for FPGA Prototyping

FPGA prototyping is a powerful way to test digital designs before final production. It combines both hardware and software techniques to create prototypes that reflect the original design. This process is key for design teams striving to perfect their hardware design. Various tools and techniques provide a solid prototyping environment. They help in the software development and hardware design processes. Engineers use these tools to transform their ideas into tangible digital circuits.

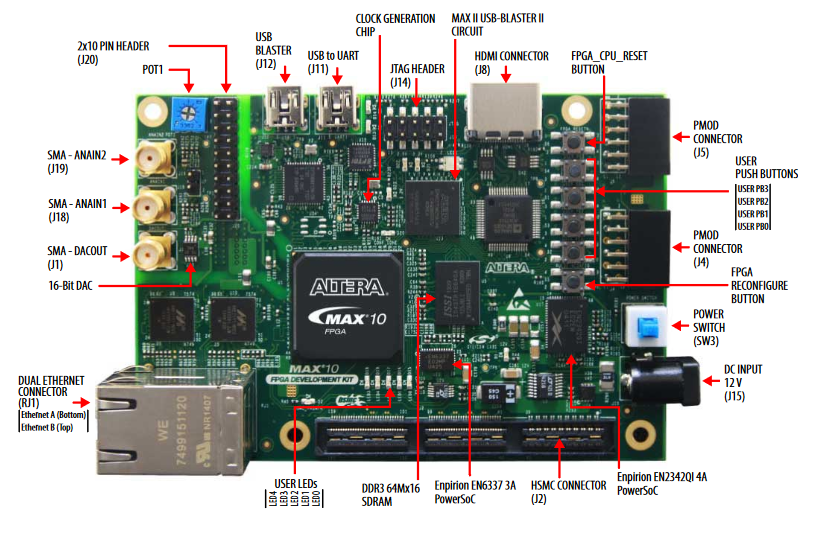

Development Boards

Development boards are essential tools in the FPGA prototyping process. They provide a physical platform for testing and refining SoC designs. These prototyping boards include necessary components for creating and adjusting electronic circuits. The boards allow design teams to prototype systems that match the original design concepts. Engineers can test functions and performance before mass production. The process also involves software development, making development boards a key part of a software team’s resources.

Synthesis Tools

Synthesis tools play a vital role in turning digital design into functional prototypes. They convert high-level design descriptions into gate-level representations. This transformation is important for hardware accelerators and digital circuits. These tools optimize the hardware design and ensure it meets strict design guidelines. They make the transition from concept to reality seamless by interpreting complex software operations. Synthesis tools are integral in the development process, bridging the gap between software simulations and real-world application.

Simulation Tools

Simulation tools offer an environment to test and verify software and digital circuits before physical prototypes are created. They mimic hardware behavior, allowing for precise evaluation of the design process. These tools are essential for navigating the complexities of SoC design and software stacks. Simulation ensures the design meets required standards and functions as intended in the final product. They help design teams foresee potential issues and refine their designs, streamlining both the prototyping process and software development.

Debugging Tools

Debugging tools are indispensable in identifying and resolving design issues during FPGA prototyping. They allow engineers to probe and test hardware and software components effectively. These tools help in pinpointing errors and ensuring seamless operation of digital circuits. By integrating software development tools with debugging capacities, teams can enhance their synthesis and prototyping efforts. Debugging tools ensure the final product is reliable and adheres to the original design without compromising performance, thus smoothing the path from conception to completion.

Step-by-Step FPGA Prototyping Process

FPGA prototyping is a vital part of hardware design, facilitating the creation of a functional model before full-scale production. It allows design teams to explore, test, and validate their digital circuits and systems. By using a structured prototyping platform, teams can achieve efficient SoC design and improve the overall development process. This guide outlines the key steps in the FPGA prototyping process, providing insights into the workflow, from the initial concept to production.

Initial Design and Specification

The FPGA prototyping journey begins with a well-defined design process. Initially, design teams outline strict design guidelines and specifications for the original design. This stage is key as it sets the foundation for the entire project. Teams consider factors such as desired functionality, performance targets, and project constraints. By having these details in place, the prototyping environment becomes much more manageable. Engineers also start considering hybrid prototyping options and potential hardware accelerators during this phase.

Synthesis and Resource Allocation

Once the design parameters are finalized, the next step is synthesis and resource allocation. Engineers use synthesis tools to transform high-level design concepts into a format suitable for FPGA implementation. This involves allocating resources within the prototyping boards to ensure optimal performance. Proper resource allocation ensures that FPGAs efficiently manage their components. The right strategy here can significantly impact the overall success of the prototyping systems.

Simulation and Testing

With the synthesized design, simulation and testing come into play. This phase involves running software simulations to validate the design’s logic and functionality. Prototyping tools allow software teams to test various scenarios, ensuring that the digital circuits behave as expected. Through virtual prototyping, engineers can identify potential issues early. This stage is critical as it helps refine concepts of software operations within the design.

Debugging and Refinement

After simulation and testing, the design often requires debugging and refinement. Engineers analyze test results to identify and fix any issues. This process may involve using a software development tool suite to tweak specific parts of the design. Continuous refinement ensures that the prototype meets all design guidelines and specifications. This step can be iterative, requiring several rounds of adjustments to optimize the hardware design fully.

Transitioning to Production

The final step in the FPGA-based prototyping process is transitioning to production. This stage involves taking the refined prototype and preparing it for mass production. Engineers finalize the software stacks and complete any remaining software development. They ensure that all digital design courses and guidelines were followed throughout the development process. A smooth transition to production requires collaboration between various teams, including software development and hardware design, to ensure the final product meets quality standards.

Applications of FPGA Prototyping

FPGA prototyping is used in hardware design due to its flexibility. It allows design teams to test digital circuits and hardware accelerators. This technique provides a fast prototyping platform for the development process. The versatile nature of FPGAs supports various digital design courses and real-world applications. They play a vital role in understanding software simulations and running software development tool suites. FPGAs can adapt to changing strict design guidelines, making them suitable for various industries. Therefore, FPGA-based prototyping is a popular choice for tech companies looking to refine original designs and concepts.

5G Network Development

FPGA prototyping is vital in the growth of 5G networks. In 5G design, speed and efficiency are key. FPGAs bridge the gap between concept and reality in SoC design. They provide a real-world prototyping environment. Design teams use this platform to explore and validate complex software stacks. Software tools used during this phase help simulate network conditions. This process ensures hardware accelerators achieve required performance levels. By implementing hybrid prototyping, experts can refine network elements, ensuring they meet global standards.

High-Performance Computing

FPGAs are essential in high-performance computing due to their ability to handle complex tasks. They enable quick iterations during the design process. Development teams often use FPGA-based prototyping to test digital circuits at high speeds. This method ensures software operation and hardware coordination. Synthesis tools convert software designs into working hardware models. This seamless transition aids research in fields like artificial intelligence and data analysis. Working with a software development platform, FPGAs enhance computing power. This capability makes them invaluable in expanding computational limits.

Video Processing Systems

In video processing, FPGA prototyping offers remarkable benefits. It supports rapid prototyping of digital circuits tailored for video applications. These platforms allow software teams to integrate their software development into the hardware design efficiently. As a result, software solutions are optimized for real-time video operations. Prototyping tools help developers test stringent design guidelines crucial for video quality. By using source software projects and pertinent software simulations, teams can develop highly efficient systems. Video processing hence achieves the necessary speed and quality without extensive hardware changes.

ASIC Prototyping

ASIC prototyping benefits greatly from FPGAs. The prototyping process involves creating a replica of the intended ASIC design. FPGA-based systems provide a cost-effective solution for this. The virtual prototyping stage involves using software simulations. This is critical to test the ASIC’s functionality and design integrity. Development teams rely on prototyping boards to create functional models of their designs. FPGAs allow the original design to be iteratively refined. It allows the team to meet strict industry standards before producing the final ASIC version. Using FPGAs leads to more efficient production and minimizes costly revisions.