What is a BGA Socket and How to Choose One?

20/03/2025, hardwarebee

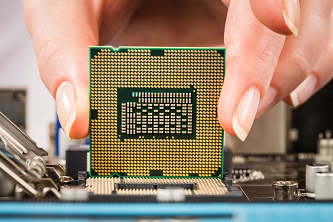

In the ever-evolving landscape of technology, choosing the right BGA package socket for your application can be a pivotal factor in achieving peak performance. BGA, or Ball Grid Array, sockets are integral components used to mount integrated circuits with precision and reliability, facilitating high-bandwidth communication among devices. Understanding the various types of BGA sockets and their unique features is essential for engineers and designers who aim to optimize their electronic assembly projects.

Proper BGA test socket selection can greatly impact the performance and longevity of electronic systems. Factors such as thermal access, insulation, and mounting options must be carefully considered to ensure compatibility and efficiency. From thermal access holes to insulation and backing plates, each characteristic of a BGA socket plays a crucial role in the overall functionality of the circuit.

This guide offers a comprehensive overview of BGA sockets and BGA test sockets, covering essential types and their applications, including elastomer sockets for high-bandwidth use. We’ll delve into installation solutions, explore performance considerations for advanced frequencies, and discuss customizable options. Whether you’re refining an existing design or embarking on a new project, this guide will equip you with the insights necessary for making informed decisions on BGA socket selection.

Understanding BGA Sockets

BGA sockets play a crucial role in modern electronics. Ball Grid Array (BGA) technology is a type of surface-mount packaging used for integrated circuits. It provides a more effective method for chip connections compared to older pin configurations. BGA sockets offer a compact solution, making them ideal for high-performance applications where space is limited. By improving signal integrity and enhancing thermal performance, these sockets cater to the needs of advanced electronic devices.

What are BGA Sockets?

BGA sockets are specialized components designed to house Ball Grid Array devices. These devices use an array of solder balls for connectivity, replacing traditional pins. The solder balls are arranged on the underside of the chip, making connections more reliable. BGA sockets are used for direct mount applications in prototypes and final products. They offer versatility in testing, burn-in applications, and can be found in low-profile designs. BGA sockets are optimized to ensure that the chip’s signals remain clear through wire in elastomer contact or spring pins. Their design varies to accommodate different shapes and sizes of chips, ensuring reliable connections and optimal performance.

Importance of Proper BGA Socket Selection

Selecting the right BGA socket is vital for device reliability and functionality. The choice impacts how well the device handles heat and maintains signal integrity. A proper socket design ensures efficient electrical performance and reduces the risks of device ball deformity or solder ball damage. For instance, low-profile fine-pitch ball grid arrays may demand a different type of socket compared to larger, lead-free designs. Adequate BGA socket selection can also enhance the performance of flip chip ball grid arrays and other chip types. Additionally, it prevents costly errors during the assembly process, making it essential to choose the right socket for each specific application.

Types of BGA Sockets

Ball Grid Array (BGA) Sockets are crucial in modern electronics due to their compact design and excellent signal integrity. There are various types of BGA Sockets, each designed to meet specific needs in electronic applications. These sockets provide a connection between the device and the circuit board without soldering the chip directly, which is beneficial for testing and prototyping. Some popular types of BGA Sockets include the SBT BGA Socket and the Direct mount socket. Others may have specific features like wire-in elastomer contact. When selecting a socket, consider factors like durability, ease of use, and compatibility with ball grid array devices. Understanding the different socket designs can help engineers choose the right one for their specific application.

Thermal Access Holes

Thermal access holes in BGA Sockets play a vital role in managing heat. Effective heat dissipation is important for maintaining device performance and longevity. These holes allow heat to escape, preventing overheating of sensitive components. Sockets with thermal access holes provide a pathway for heat to move away from the device. This design is especially beneficial in burn-in applications, where extended testing can generate significant heat. Engineers must consider thermal management when designing applications involving high power or high-speed devices.

![]()

Insulation Plates and Backing Plates

Insulation plates and backing plates are integral to the safety and stability of BGA Sockets. Insulation plates help prevent short circuits by creating a barrier between the socket and the circuit board. Backing plates provide structural support, ensuring that the socket and the chip remain securely in place during use. These plates are essential for maintaining signal integrity and protecting the device from mechanical stress. They are especially important in applications where the socket might be subjected to physical movement or vibration. Together, insulation and backing plates ensure reliable performance of ball grid array technology.

Existing Mounting Holes

Existing mounting holes are pre-drilled holes in a circuit board or component used for securing BGA Sockets. They allow for easy and accurate placement of the socket, ensuring alignment with the array of solder balls on the chip. Using existing mounting holes can simplify the installation process, making it more efficient and reducing the risk of error. When designing a new prototype or device, it’s important to consider whether existing mounting holes are available or if new ones need to be created. Properly utilizing these holes ensures the ball matrix contact technology functions as intended, enhancing the overall reliability of the electronic device.

High-Bandwidth Applications

BGA sockets play a vital role in high-bandwidth applications. These sockets are crucial to the performance of devices relying on rapid data transmission. With the rise of technology that demands increased signal integrity, BGA sockets provide an efficient solution. They accommodate varying densities and speeds required in modern applications.

Ball Grid Array (BGA) devices are known for their compact design and ability to handle complex circuits. The sockets used for these devices ensure secure and reliable connections. This connection is vital for providing optimal performance, as even slight signal interruptions can hinder overall efficiency. The use of ball grid array technology is crucial to meeting the fast-growing need for efficient high-bandwidth applications.

One of the standout features of BGA sockets is their adaptability. They support diverse configurations, helping designers push the limits of speed and data throughput. These sockets also help reduce interference, making them ideal for high-frequency environments. This makes BGA sockets an essential element in today’s tech-driven world.

Elastomer BGA Sockets

Elastomer BGA sockets provide a flexible and effective solution for various applications. These sockets are preferred in scenarios that require frequent insertion and removal. Their design uses wire in elastomer contact, allowing for reliable connections without permanent soldering. This flexibility makes them popular for prototyping and testing phases in electronics development.

The use of elastomer in BGA sockets enhances their resilience. Unlike traditional sockets, elastomer variants handle wear better due to their durable material. This feature ensures that even with repeated use, the signal integrity remains intact. Specialists often choose elastomer sockets for their ability to withstand rigorous testing conditions.

The versatility of elastomer BGA sockets extends to several other benefits. They offer low-profile designs, making them suitable for compact and intricate setups. Furthermore, they accommodate various size configurations, from standard chips to large tin balls. This adaptability makes elastomer BGA sockets a viable choice for many electronic applications, ensuring they remain a cornerstone in the future of technology development.

Installation and Mounting Solutions

Choosing the right installation and mounting solution is key to the success of a BGA socket application. BGA sockets are used to interface with Ball Grid Array devices, ensuring the connection between chips and circuit boards. Various mounting options can affect signal integrity, longevity, and ease of maintenance. From solderless to epoxy-mounted methods, each approach offers unique benefits and potential challenges. Understanding these options can help in selecting the best solution for specific burn-in applications or prototype testing with BGA sockets.

Direct Mount Solderless Solutions

Direct mount solderless solutions provide a flexible way to connect BGA sockets without solder balls or other traditional terminations. These solutions often use wire in elastomer contact methods or spring pins to establish seamless connectivity. One major advantage is their ease of use in rapid prototyping and testing environments, such as for SBT BGA Sockets. Unlike soldered connections, which might cause device ball deformity or alignments issues, solderless methods allow for quick changes and adjustments. They can maintain high levels of signal integrity, ensuring that the communication between electronic components stays clear and reliable.

Evaluating Epoxy-Mounted Solutions

Epoxy-mounted solutions involve using an adhesive agent to secure BGA sockets firmly onto a circuit board. This approach can offer a robust and stable attachment, ensuring long-term usage without frequent reinstallation needs. Plastic Ball Grid Array and other BGAs can benefit from this method as it fits both large-scale productions and specific usage like chip ball grid array applications. However, it’s vital to evaluate aspects such as curing time and thermal resistance to ensure that the epoxy doesn’t interfere with the chip’s performance. In environments requiring high durability, the epoxy method reduces risks associated with ball terminations or device ball deformity, making it suitable for lead-free solder environments or high-stress conditions.

Performance Considerations

When selecting a BGA socket, performance is a critical factor. The right socket must ensure signal integrity while fulfilling your design requirements. This involves selecting materials that resist warping and provide a stable connection. It is also essential to assess how the socket design will impact the device’s operation, especially for those used in high-frequency applications. Consider the temperature ranges it can withstand during burn-in applications and understand how spring pin designs can improve contact reliability. With proper design, a socket can accommodate the challenges of wire in elastomer contact and other advanced technology needs.

Pinout and Pitch Options

Pinout and pitch options are vital for optimizing BGA socket performance. Pinout refers to the arrangement of pins on the socket, matching it to the corresponding device, such as a chip ball grid array. Pitch options, the distance between ball terminations, influence how compact a design can be. A low-profile ball grid array is often preferred in space-constrained applications. Standard pitch options vary, accommodating diverse needs from a wide array of solder balls to more specialized configurations like a low-profile fine-pitch ball grid array. These options allow engineers to align the socket with specific device requirements, ensuring reliable connectivity.

GHz Performance Capabilities

The growing demand for high-speed applications means a BGA socket should deliver up to 30GHz and 27GHz performance capabilities. This means the socket must efficiently handle high-frequency signals without signal degradation, preserving signal integrity. A Direct mount option might be ideal as it can reduce noise and improve performance. Ball grid array devices with high GHz capability often utilize advanced ball matrix contact technology to maintain connectivity under extreme conditions. It is crucial to consider how these capabilities align with existing network requirements and future technological advancements to maximize performance in diverse applications.

Custom BGA Socket Solutions and Services

Custom BGA sockets are critical in today’s fast-paced technology world. These tailor-made offerings address unique challenges and requirements of businesses, ensuring optimal performance and efficiency.

Key Features of Custom Solutions:

- Personalization: Solutions are designed to meet specific business needs, enhancing productivity.

- Scalability: Custom solutions grow with your business, accommodating expanding operations seamlessly.

- Integration: Easily integrates with existing systems, maintaining signal integrity and avoiding disruptions.

- Flexibility: Adapts to changing market demands and technological advancements.

Services Offered:

- Consultation and Planning: Expert guidance to outline objectives and potential solutions.

- Design and Development: Creating a blueprint tailored to specific needs, ensuring features like low-profile ball grid array and chip array ball grid technology.

- Implementation and Support: Smooth integration and ongoing assistance to resolve issues and optimize performance.

- Training and Resources: Equipping teams with the necessary skills to use new solutions effectively.

Businesses opting for custom BGA socket solutions often experience improved operational efficiency and competitive advantage. By focusing on adaptability and integration, these services ensure that companies can thrive in an ever-evolving technological landscape.