Powertrain System: Ultimate Guide

21/03/2025, hardwarebee

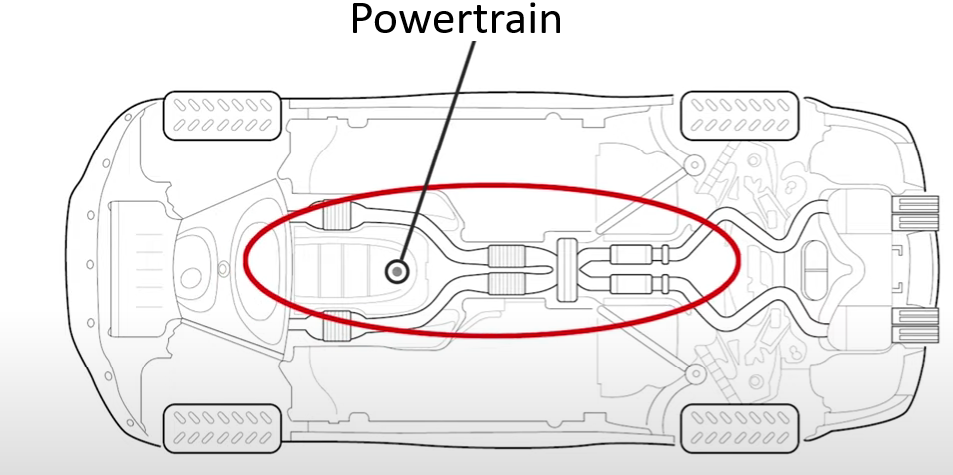

Understanding the powertrain system is key to unleashing a vehicle’s full potential. At the core of every vehicle, this intricate assembly of components is not just about propulsion—it’s the heartbeat that defines efficiency, performance, and reliability. With increasing advancements, from internal combustion engines to electrified drives and cutting-edge fuel cell technologies, the landscape is dynamically shifting.

image source: Honda

Powertrain systems require the seamless blending of data and smart technologies to optimize both functionality and sustainability. Rigorous testing environments, quality management certifications, and the maintenance of specific components like engines, transmissions, and axles ensure these systems operate flawlessly, paving the way for enhanced vehicle performance and longevity.

This guide will delve into the nuances of powertrain systems, offering insights into their types, testing facilities, maintenance services, and the numerous benefits of ensuring their optimal operation. We will explore the essential components and introduce key market players, equipping you with a comprehensive understanding of what powers the vehicles of today and tomorrow.

Understanding Powertrain Systems

Powertrain systems are the core of any motor vehicle. They include all the key components that work together to move the vehicle. These systems convert mechanical energy to kinetic energy, allowing the vehicle to function efficiently. In modern powertrains, this often involves a combination of the internal combustion engine and electric powertrains like electric motors. The goal is to achieve maximum power output while maintaining fuel efficiency. As technology evolves, so do these systems, becoming more sophisticated and efficient to meet the demands of a wide range of road surfaces and driving conditions.

Overview of Powertrain Components

Powertrain components include several critical parts, each playing a vital role in the vehicle’s performance. The internal combustion engine is often the heart, providing the necessary engine power. Electric motors are common in electric and hybrid powertrains, offering cleaner and more efficient energy conversion. The drive shaft transmits this power to the rear axle or front wheels, depending on whether the vehicle is a Four-Wheel Drive, Front-Wheel Drive, or Rear-Wheel Drive. Another important element is the powertrain control module, which ensures the entire powertrain operates smoothly. Electronic Control Units and battery management systems further enhance efficiency, especially in electric vehicles. Together, these components form a quality powertrain that delivers a broad range of capabilities and functions.

Importance of Data and System Integration

Data and system integration are crucial for optimizing powertrain systems. By tapping into Electronic Control Units, vehicles can adjust their operations to improve fuel economy and energy use. This integration allows for real-time adjustments based on road surface conditions and driving habits, ensuring the vehicle operates at peak performance. Key data from Battery packs and power output metrics can inform battery management strategies to enhance overall electric powertrains efficiency. System integration also supports the coordination of internal combustion engines and electric motors in hybrid models, allowing for seamless transitions between power sources. Thus, the effective use of data integration results in smarter, more adaptable vehicles that meet modern driving demands.

Types of Powertrain Systems

Powertrain systems are key components in motor vehicles. They convert energy into motion using a broad range of technologies. The main types of powertrain systems include Internal Combustion Engines, Electrified Drives, and Fuel Cell Systems. Each system has unique features that impact vehicle performance and fuel efficiency. Understanding these systems helps in choosing the right vehicle for different driving needs. Factors such as fuel economy, power output, and mechanical energy efficiency are essential in evaluating them. Let’s explore these types and see how they turn potential energy into movement.

Internal Combustion Engines

Internal combustion engines (ICE) have powered vehicles for over a century. They convert fuel into mechanical energy by igniting fuel within the engine’s cylinders. This process involves air and a fuel mixture which ignites under pressure to create controlled explosions. The explosions drive pistons that turn the crankshaft, transferring energy to the drive shaft. These engines can power front-wheel, rear-wheel, or four-wheel drive systems, depending on the design. Despite the arrival of newer technologies, internal combustion remains popular for its robustness and wide range of applications, though advancements continue to improve fuel efficiency.

Electrified Drives

Electrified drives are a modern powertrain option that includes electric and hybrid powertrains. Electric powertrains use electric motors for power output, relying on battery packs and electrical energy to function. Hybrid powertrains combine an electric motor with an internal combustion engine to improve fuel efficiency and reduce emissions. These systems use Electronic Control Units to manage both energy sources, offering a balance between electric and fuel power. The entire powertrain manages energy distribution for smooth performance, adapting to varied road surfaces. Electrified drives are popular for their enhanced fuel economy and lower environmental impact.

Emerging Technologies: Fuel Cell Systems

Fuel cell systems are an emerging technology in modern powertrains. They generate power by combining hydrogen with oxygen to produce electricity, releasing only water as a by-product. This process doesn’t involve combustion, making it a clean energy option. Fuel cells generate electrical energy efficiently, driving electric motors without batteries. Vehicle manufacturers see potential in fuel cells for long-range driving with zero emissions. As research progresses, fuel cell systems may become a prominent choice for eco-friendly motor vehicles, contributing to advances in sustainable transport. Their potential for energy conversion makes them a promising future powertrain solution.

Test Facilities and Specifications

Test facilities are crucial in developing powertrain systems for motor vehicles. They ensure that each component, from the internal combustion engine to the electric motor, operates seamlessly. These facilities simulate real-world conditions to test how powertrains perform across a wide range of road surfaces and driving scenarios. This broad range of testing helps improve fuel economy, enhance power output, and refine mechanical energy transmission. With the shift towards electric powertrains and hybrid powertrains, these facilities also focus on testing battery management and battery packs to ensure efficiency. Overall, test facilities are vital for ensuring that the entire powertrain system operates at peak performance under various conditions.

Significance of Test Facility Specification Levels

Test facility specification levels outline the standards and capabilities needed to assess powertrain systems effectively. These specifications ensure that a facility can accurately simulate different driving conditions, from Front-Wheel Drive to Four-Wheel Drive scenarios. By adhering to these specifications, test facilities can evaluate a powertrain’s response to a diverse range of situations. This includes testing on different road surfaces and under varying weight conditions. The higher the specification level, the more precise and comprehensive the testing. This capability is especially significant for modern powertrains, which integrate complex systems like Electronic Control Units and powertrain control modules. Ensuring these systems work correctly is imperative for maintaining high levels of fuel efficiency and overall powertrain reliability.

Role of Quality Management Certification

Quality management certification plays a critical role in maintaining the standards of test facilities. These certifications signify that a facility follows rigorous guidelines to ensure accurate and reliable testing. They are essential for building confidence in the test results of powertrain systems. Certifications help ensure that every aspect of testing, from analyzing mechanical energy conversion to evaluating engine power, meets international standards. They also endorse the facility’s ability to handle complex evaluations, such as those required for hybrid powertrains and electric powertrains. With quality management certification, manufacturers can trust the data used to improve fuel economy and enhance the reliability of vehicle powertrains.

Accreditation and Reliability Standards

Accreditation and reliability standards are vital in ensuring the dependable performance of test facilities. Accreditation acts as a formal recognition that a testing facility meets specific quality and performance criteria. It ensures that the facility has the tools and expertise to test various powertrain components accurately. This includes components like the drive shaft, rear axle, and battery packs. Reliability standards, on the other hand, focus on maintaining consistent test results. These standards confirm that the testing methods yield reliable data under different conditions and over time. Combined, accreditation and reliability standards help verify that the test facility can truly evaluate the entire powertrain system’s performance and ensure quality powertrain development.

Testing Environments

Testing environments play a crucial role in the development of efficient automotive powertrain systems. These controlled settings allow engineers to simulate various conditions that a vehicle might encounter on the road. This includes assessing how well the powertrain handles wide ranges of temperatures and road surfaces. Testing environments help ensure that key components like the electric motor, internal combustion engine, and drive shaft work seamlessly together. By replicating real-world scenarios, manufacturers can fine-tune systems for fuel efficiency and quality performance. These tests are essential to achieving the best engine power and fuel economy while ensuring safety and reliability in all types of motor vehicles.

Importance of Enclosed Test Cells

Enclosed test cells are vital for accurate powertrain testing. They provide a controlled space where variables can be closely monitored and adjusted. This includes factors like temperature, humidity, and road conditions, which might affect power output and mechanical energy transfer. By testing within these cells, engineers can focus on how electronic control units and battery management systems respond. These cells help identify and address any issues in electric powertrains or hybrid powertrains, ensuring top-notch fuel efficiency. Ultimately, enclosed test cells give engineers the ability to test a broad range of scenarios, leading to the development of modern and efficient powertrain systems.

Powertrain Maintenance Services

Powertrain systems are crucial in motor vehicles as they convert various forms of energy into kinetic energy, moving the vehicle forward. Maintaining your vehicle’s powertrain ensures optimal performance and longevity. The powertrain comprises several key components, including the engine, transmission, drive shafts, and differentials. Regular maintenance services help avoid expensive repairs and improve fuel efficiency. These services include inspections, part replacements, and fluid changes to keep components such as the internal combustion engine and electric motor in top condition. A well-maintained powertrain not only enhances the vehicle’s power output but also contributes to better fuel economy.

Engine Replacement and Repair

Engines are the heart of any vehicle’s powertrain system. Whether dealing with an internal combustion engine or an electric motor, proper maintenance is essential. Engine repair addresses issues that can arise from wear and tear, like leaks and reduced performance. Regular check-ups can prevent minor problems from becoming major ones. Sometimes, an engine replacement becomes necessary if the damage is beyond repair. Replacing the engine can restore the entire powertrain, offering a new lease on life for your vehicle. With the right care and timely repairs, the engine can perform efficiently across a broad range of road surfaces.

Transmission and Transaxle Replacement

The transmission is a key component in the powertrain system, responsible for controlling the power output from the engine to the wheels. A functioning transmission ensures that the vehicle operates smoothly by efficiently managing mechanical energy. Regular checks and fluid replacements can prolong its lifespan. However, over time, it may require repair or replacement. Transaxle systems, found in Front-Wheel Drive vehicles, combine the transmission and differential in one assembly. Proper maintenance of these systems extends their life and maintains the vehicle’s fuel efficiency. Replacing a faulty transmission or transaxle can improve overall driving performance.

Differential and Axle Repair

Differentials and axles are vital parts of the powertrain, facilitating smooth and efficient movement. The differential allows the wheels to rotate at different speeds, particularly during turns, enhancing vehicle handling. Axles transfer engine power to the wheels, supported by the drive shaft. Regular inspection and maintenance can prevent issues such as wear or damage to these components. Whether for Rear-Wheel Drive, Front-Wheel Drive, or Four-Wheel Drive configurations, differential and axle repairs ensure stability and control. Proper care and timely repairs of these components help maintain the vehicle’s capability to handle a wide range of driving conditions.

Benefits of Well-Maintained Powertrain Systems

A powertrain system is a vital component of a motor vehicle, responsible for generating and delivering power. It includes the internal combustion engine, electric motor, and other key components like the drive shaft and rear axle. A well-maintained powertrain system offers several advantages. These benefits extend to the vehicle’s performance, lifespan, and efficiency. Regular maintenance helps ensure that all parts are working smoothly together. This system also plays a crucial role in fuel economy, which can lead to cost savings in the long run. By understanding the importance of maintaining your powertrain system, you can keep your vehicle running at its best.

Enhanced Vehicle Performance

A well-kept powertrain system results in enhanced vehicle performance. When each part of the system is in good condition, the entire powertrain can operate efficiently. Modern powertrain systems often use electronic control units to monitor performance. These units make sure that the power output is optimal on various road surfaces. With a quality powertrain, you can achieve better acceleration and smoother gear shifts. This contributes to an enjoyable driving experience.

The benefit of good performance is especially noticeable in different types of driving conditions. For example, Four-Wheel Drive systems depend on a reliable powertrain to provide good traction. This is essential when driving on rough or uneven surfaces. A well-maintained system ensures that mechanical energy is efficiently converted into kinetic energy. This results in steady and reliable vehicle movement.

Longevity of Vehicle Components

Maintaining a powertrain system is key to extending the lifespan of vehicle components. Each part of the system works together to ensure smooth operation and optimal performance. When components are kept in top condition, they reduce the risk of breakdowns. This can, in turn, prevent costly repairs. Components such as the engine, electric motor, and drive shaft all benefit from regular check-ups.

A well-maintained system also contributes to better fuel efficiency. Improved fuel economy means less wear and tear on the engine and other key components. The powertrain control module can efficiently manage engine power and fuel distribution. This reduces unnecessary strain on parts over time. Regularly checking and replacing elements like the battery packs and ensuring proper battery management will also add to the longevity of your vehicle’s components.

In essence, taking care of your powertrain system not only boosts performance but also extends the life of your vehicle. Regular maintenance helps avoid unnecessary expenses and keeps your vehicle in top shape for a wide range of driving conditions.

Essential Components of a Powertrain System

A powertrain system is the heart of any motor vehicle, transforming energy into motion. It ensures that engine power drives the vehicle forward or backward. This complex system includes components like the engine, transmission, drive shafts, and axles. Each piece works harmoniously to provide efficient power output. Powertrain systems can vary widely, from traditional internal combustion engines to modern electric powertrains, adapting to different road surfaces and vehicle types. By integrating electronic control units, these systems optimize fuel efficiency and overall performance. Understanding the key components and how they interact is crucial for anyone interested in automotive mechanics.

Transmission and Transaxle

The transmission and transaxle are crucial for managing a vehicle’s engine power. They transfer mechanical energy from the engine to the drive shafts, regulating power output based on speed and load. Transmissions can be automatic, manual, or a combination. A transaxle integrates both the transmission and differential into one unit, often found in front-wheel drive vehicles. They adjust gear ratios, ensuring the engine runs efficiently across a broad range of speeds. This system is essential for maintaining smooth acceleration and deceleration. In electric powertrains, transmissions may differ but still prioritize efficiency and performance.

Differential and Axles

The differential and axles play a crucial role in distributing power to the wheels. The differential splits engine power between the wheels, allowing them to rotate at different speeds. This function is vital when turning, as the inner and outer wheels travel different distances. Axles then deliver this power directly to the wheels, accommodating various road surfaces and driving conditions. Vehicles may have front-wheel drive, rear-wheel drive, or four-wheel drive, each with unique axle setups. Quality powertrain systems ensure that differentials and axles work seamlessly, providing optimal traction and stability for a safe driving experience.

Companies Provide Powertrain Systems, Modules and ICs

Powertrain systems are crucial for vehicle performance. They include the engine, transmission, drive shaft, and other components that deliver power to the car. Many companies specialize in providing these systems and their key components.

Companies Specializing in Powertrain Systems:

- Bosch: Offers a broad range of powertrain solutions, from electric powertrains to hybrid options.

- ZF Friedrichshafen AG: Known for its innovative transmission systems and electronic control units.

- Continental AG: Provides quality powertrain systems, focusing on fuel efficiency and reducing emissions.

IC Companies for Powertrain Systems:

- Infineon Technologies: Offers a wide range of integrated circuits for effective power management.

- NXP Semiconductors: Produces ICs that enhance power output and control in powertrain systems.

- Renesas Electronics: Supplies ICs that improve the efficiency and reliability of entire powertrain systems.

T

hese companies cater to the demands of modern powertrains, such as engine power and kinetic energy management. They ensure vehicles can handle various types of road surfaces and deliver optimal fuel economy, whether in Four-Wheel Drive or Front-Wheel Drive configurations.